What is Fully Biodegradable Polyester?

Fully biodegradable polyester is a type of environmentally friendly material that can be completely decomposed by microorganisms in the natural environment. Compared with traditional plastics, it has significant ecological advantages. Fully biodegradable polyester can not only be degraded into water, carbon dioxide and biomass, but also uses renewable resources (such as plant starch, corn, sugarcane, etc.) as raw materials, avoiding dependence on petroleum resources. Unlike conventional plastics that take hundreds of years to degrade, the degradation time of fully biodegradable polyester is usually shorter, which can effectively reduce plastic pollution.

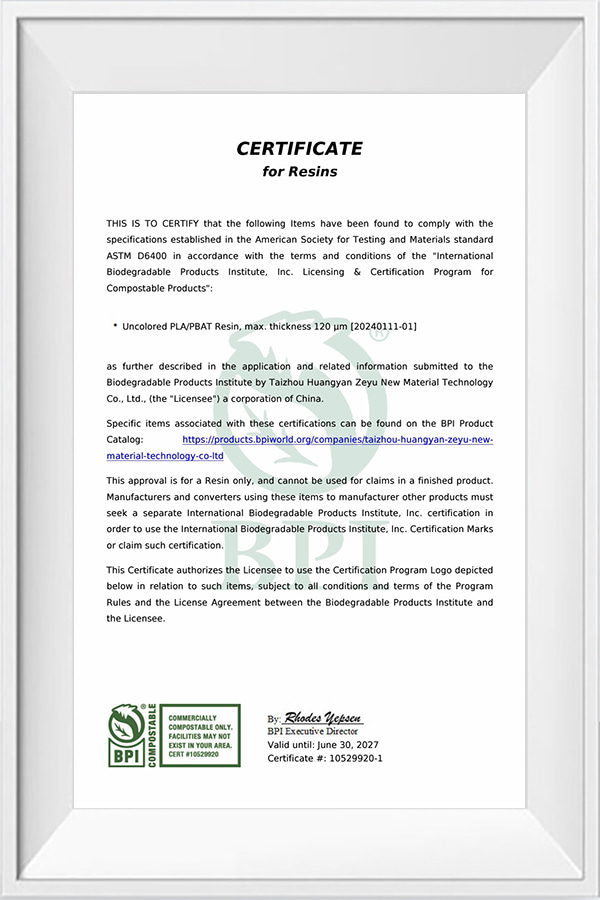

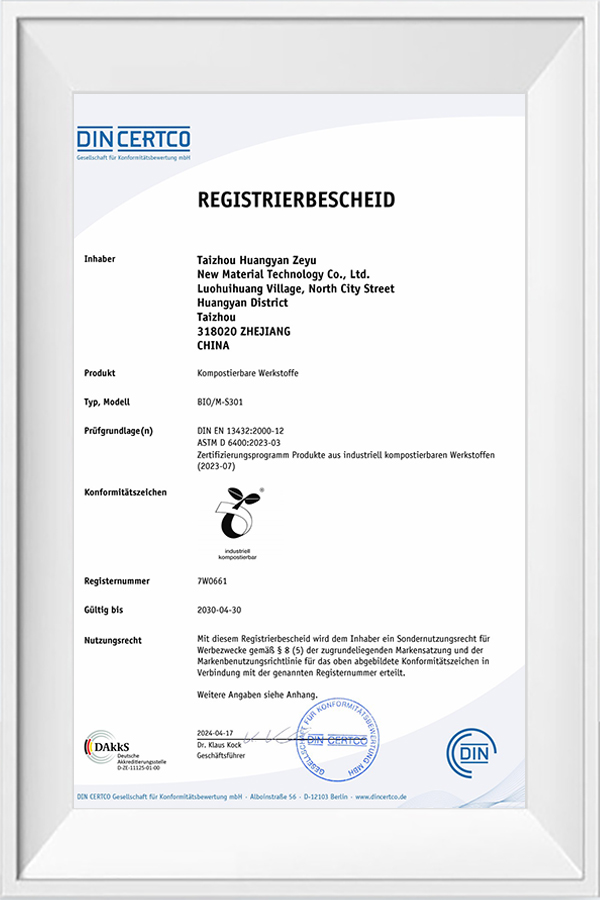

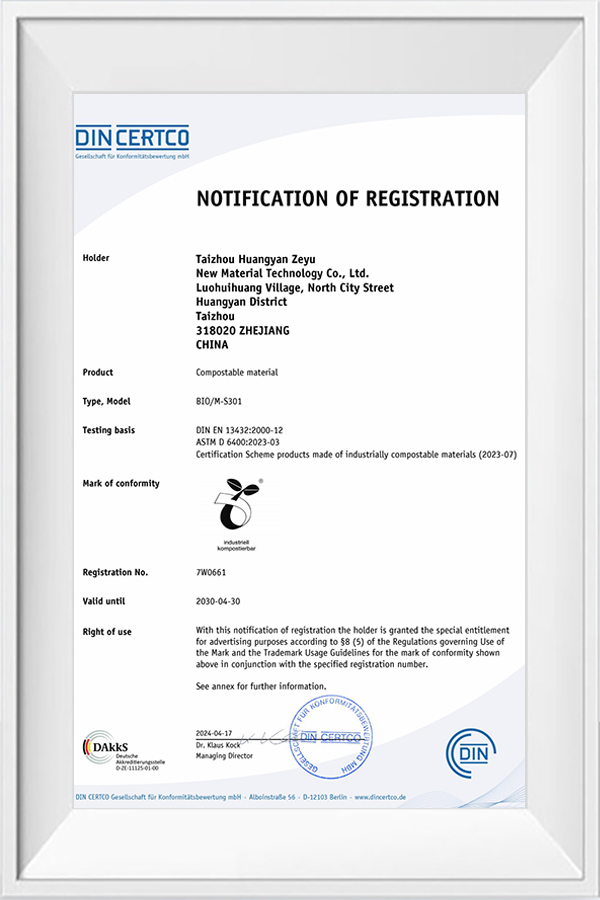

Technically, fully biodegradable polyester mainly includes PBAT, PLA and other materials, which are environmentally friendly during the production process and do not produce toxic by-products. Fully biodegradable polyester is widely used in food packaging, agricultural films, medical devices, textiles and other fields, and is an ideal choice to replace traditional plastics.

What are the technical advantages of fully biodegradable polyester?

The technical advantages of fully degradable polyester are mainly reflected in the following aspects:

1. Degradability: Compared with traditional plastics, fully degradable polyester can be completely degraded by microorganisms in the natural environment, and no harmful substances are produced during the degradation process. Its degradation rate is usually fast, which not only avoids plastic pollution, but also reduces the long-term impact of plastic waste on the environment.

2. Renewability: The raw materials of fully degradable polyester mostly come from renewable resources, such as plant starch and corn, which can be continuously provided by agriculture, fundamentally reducing dependence on non-renewable resources such as oil, and meeting the needs of global sustainable development.

3. Non-toxicity: During the use, degradation and waste treatment of fully degradable polyester, no toxic residues will be released, so there is no negative impact on the ecological environment and human health, especially suitable for food packaging and medical products and other fields with high health requirements.

4. Processing performance: Fully degradable polyester can be processed by existing plastic processing equipment (such as injection molding, blow molding, extrusion, etc.), without the need for special equipment modification. This enables the production cost of fully degradable polyester to compete with traditional plastic materials while gradually reducing.

How does Taizhou Huangyan Zeyu New Material Technology Co., Ltd. promote the development of fully degradable polyester?

Taizhou Huangyan Zeyu New Material Technology Co., Ltd. has made remarkable achievements in the research and development and industrialization of fully degradable polyester. The following are the company's main strategies to promote the development of fully degradable polyester:

1. Professional R&D team: Zeyu New Materials has a strong R&D team composed of professors and doctors, focusing on the technical research of fully degradable polyester materials. The team has accumulated a deep theoretical foundation and practical experience in the fields of degradation mechanism, molecular design and performance optimization of plastic materials, and continues to promote the innovation and upgrading of fully degradable polyester technology.

2. Industry-university-research cooperation: Zeyu New Materials has actively established in-depth cooperative relations with well-known domestic scientific research institutions, such as the Institute of Physical Chemistry of the Chinese Academy of Sciences, Ningbo Institute of Materials Technology and Engineering, Beijing Technology and Business University, etc. These collaborations enable the company to keep up with the forefront of the industry, timely transform scientific research results into applicable products, and enhance the performance and market competitiveness of fully degradable polyester.

3. Transformation of technological achievements: Through continuous technological research and development and process optimization, Zeyu New Materials has successfully launched a variety of fully biodegradable polyester products suitable for the fields of agriculture, medical treatment and packaging. The company is committed to solving problems in the degradation rate, strength, processability and other aspects of the material to meet the needs of different industries.