Fully biodegradable ultra-thin film materials: pioneers of green innovation that integrate environmental protection and high performance

Fully biodegradable ultra-thin film material is a type of environmentally friendly polymer film materials based on fully biodegradable polyesters and finely modified through advanced processes. The core raw materials of this type of material include bio-based or natural polymers such as PBAT, PLA and degradable starch, all of which come from renewable resources and are in line with the concept of green and sustainable development. PBAT is widely used for its flexibility and degradability, while PLA is known for its excellent mechanical strength and transparency. The addition of starch not only reduces costs, but also increases the biodegradation rate of the material, so that the overall performance and eco-friendliness are well balanced.

Through advanced blending modification technology and processing technology, these raw materials are scientifically proportioned to form film products with ultra-thin thickness (usually at the level of several microns), high flexibility and excellent transparency. Ultra-thin films are not only light, thin and soft, suitable for industrial production processes such as high-speed film blowing and extrusion, but also can ensure good mechanical strength and durability, meeting the needs of modern packaging for lightweight, transparent and durable materials. At the same time, the material surface is smooth, non-toxic and tasteless, meeting strict standards such as food safety and medical hygiene, ensuring the wide application and safety.

After use, the fully biodegradable ultra-thin film material can be completely degraded by microorganisms in the soil under natural environmental conditions, converted into water and carbon dioxide, and achieve harmless treatment. Unlike traditional plastics, this degradation process avoids environmental problems such as long-term residue, accumulation of plastic particles and soil pollution, and fundamentally solves the dilemma of "white pollution". For this reason, this material has gradually replaced traditional non-degradable plastics in many fields such as packaging, agricultural covering film, and protective film for electronic products, becoming an important support for promoting green circular economy and sustainable development. With the continuous advancement of technology and the growth of market demand, fully biodegradable ultra-thin film materials are becoming an innovative model of both environmental protection and high performance.

Advantages of fully biodegradable ultra-thin film materials

1. Good biodegradability: Fully biodegradable ultra-thin film material can be decomposed by microorganisms in the natural environment and eventually converted into water and carbon dioxide without harmful residues. Usually its degradation cycle is 3-6 months. This feature significantly reduces the accumulation of traditional plastic mulch and packaging materials in soil and water, avoiding the formation of "white pollution". This rapid degradation not only meets the requirements of environmental protection policies, but also promotes the development of the circular economy and the process of sustainable social development.

2. Flexible and strong, suitable for high-speed processing: Although the material is ultra-thin, it has been specially modified to maintain good flexibility and mechanical strength, and can withstand the stringent requirements of industrial processing technologies such as high-speed film blowing, extrusion and calendering. This makes the production line run efficiently and the product molding quality stable, which is conducive to large-scale, industrialized production and reduces production costs. At the same time, flexibility ensures that it is not easy to break during transportation and use, improving user experience.

3. Meet the packaging industry's demand for light and transparent materials: The material has high transparency and good visual effects, which meets the requirements of modern packaging for aesthetics. The ultra-thin design not only saves material usage and reduces resource consumption, but also reduces packaging weight and transportation costs. The soft and easy-to-seal characteristics make it very suitable for use in food packaging bags, cling film and other fields with high requirements for packaging performance and food safety.

4. Excellent weather resistance and mechanical properties: The fully biodegradable ultra-thin film material has been modified by a special process and has strong UV resistance and heat and cold resistance, and can adapt to a variety of complex environmental conditions. This feature ensures that its performance will not decline due to environmental changes in applications such as electronic product protective films and agricultural covering films, effectively protecting products and crops and extending their service life.

5. Wide range of applications:

Food packaging: safe and non-toxic, in line with food contact material standards, keeping food fresh and extending shelf life.

Electronic product protective film: provides excellent scratch, dust and impact protection, and can be degraded after use, reducing the pressure of electronic waste on the environment.

Agricultural covering film: improves the growth environment of crops, promotes the improvement of yield and quality, can be naturally degraded after use, reduces soil pollution, and supports the development of green agriculture.

6. Promote green transformation and sustainable development: The use of fully biodegradable ultra-thin film materials can help companies meet increasingly stringent environmental protection regulations and green procurement standards at home and abroad, and enhance the image of corporate social responsibility. At the same time, by reducing environmental pollution and resource waste, promoting the green transformation of industries such as packaging and agriculture, and promoting a win-win situation of economic and environmental benefits.

Taizhou Huangyan Zeyu New Material Technology Co., Ltd.'s R&D and market advantages in the field of fully biodegradable ultra-thin films

As China's leading high-tech enterprise in green new materials, Taizhou Huangyan Zeyu New Material Technology Co., Ltd. focuses on the research and development and application promotion of fully biodegradable plastics and bio-based plastics. The company has a complete independent R&D system and an advanced material modification platform. Relying on the deep technical accumulation of renewable resources such as PBAT, PLA and starch, it accurately controls the molecular structure and performance regulation of film materials to improve the flexibility, transparency and mechanical strength of materials. The company maintains close industry-university-research cooperation with many well-known domestic universities and research institutes to promote the deep integration of basic theory and application technology, and realize the innovation and optimization of the entire chain from core raw materials to finished film materials. This R&D strength not only ensures that ultra-thin film materials have excellent physical properties and stable biodegradation efficiency in practical applications, but also enables products to customize performance indicators according to different customer needs to meet the stringent requirements of diversified application scenarios in the fields of packaging, agriculture and electronics.

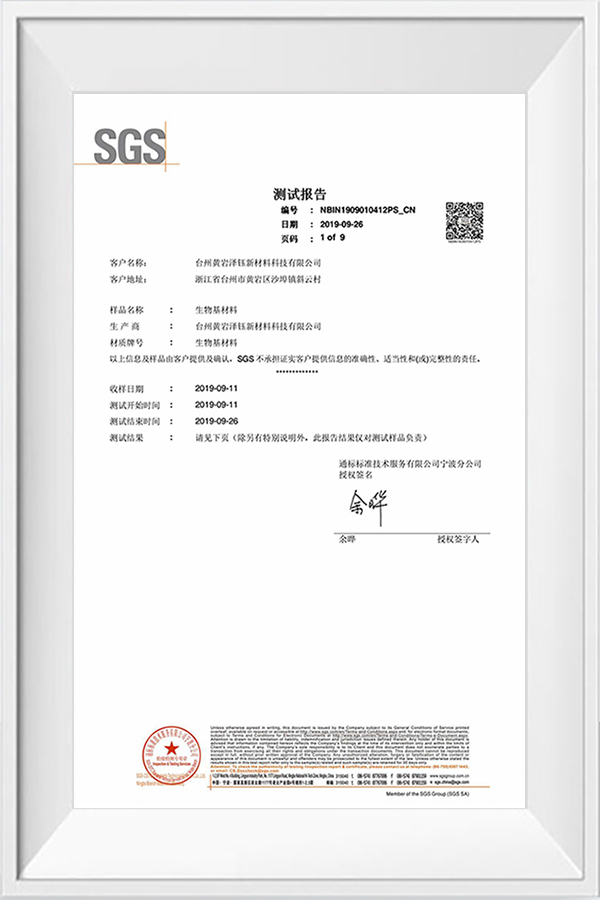

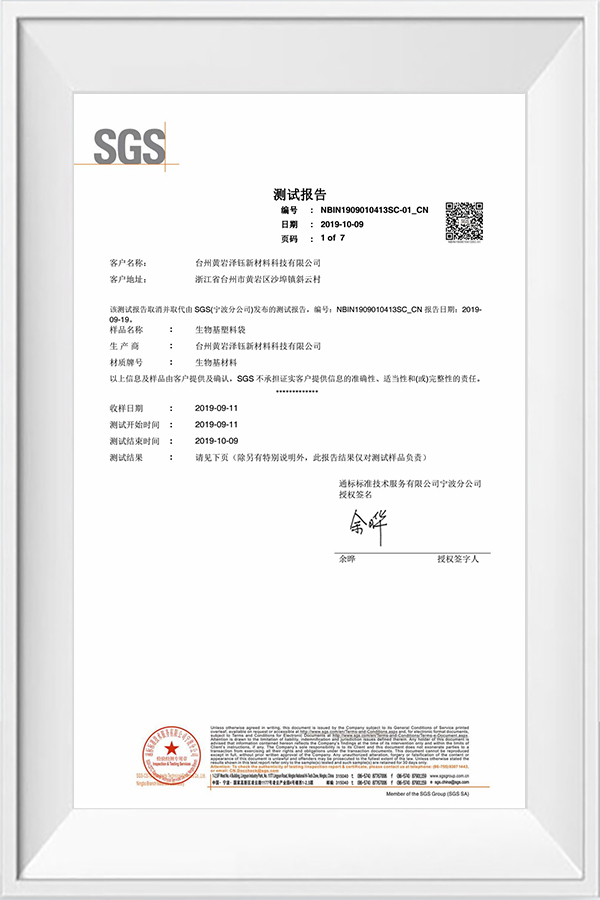

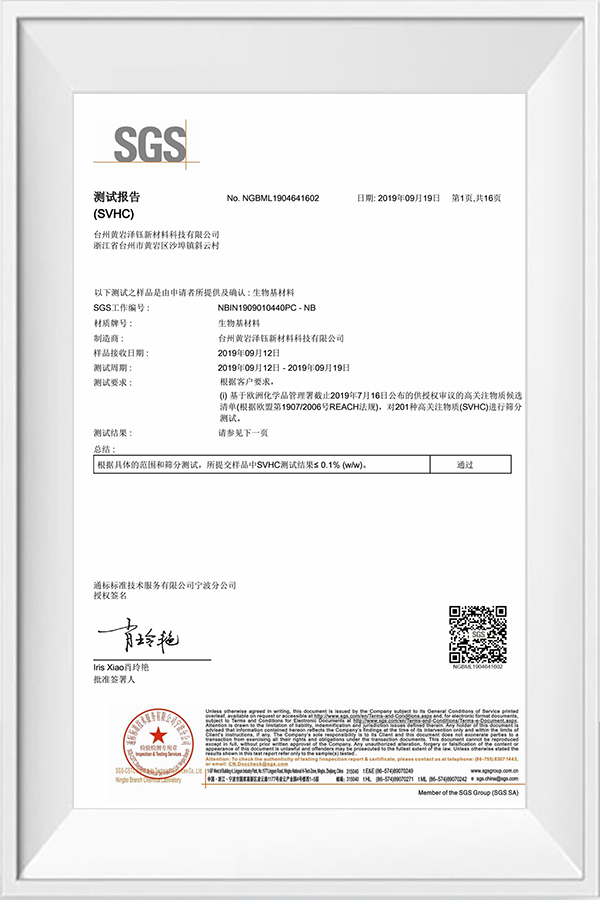

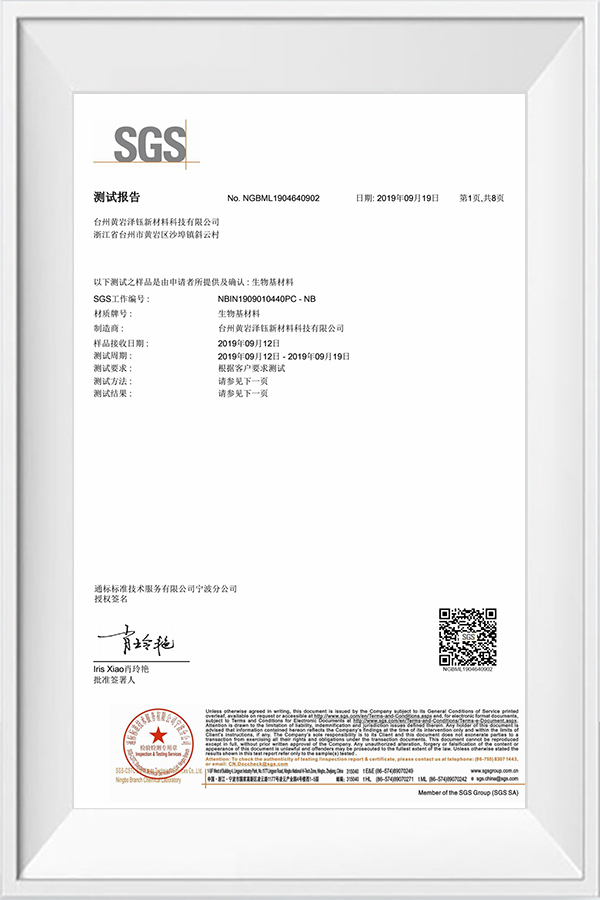

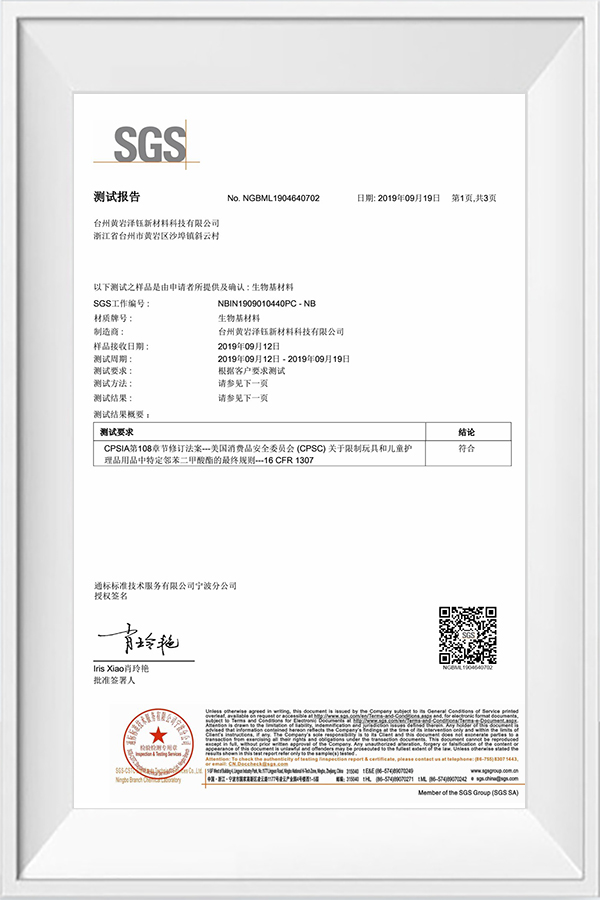

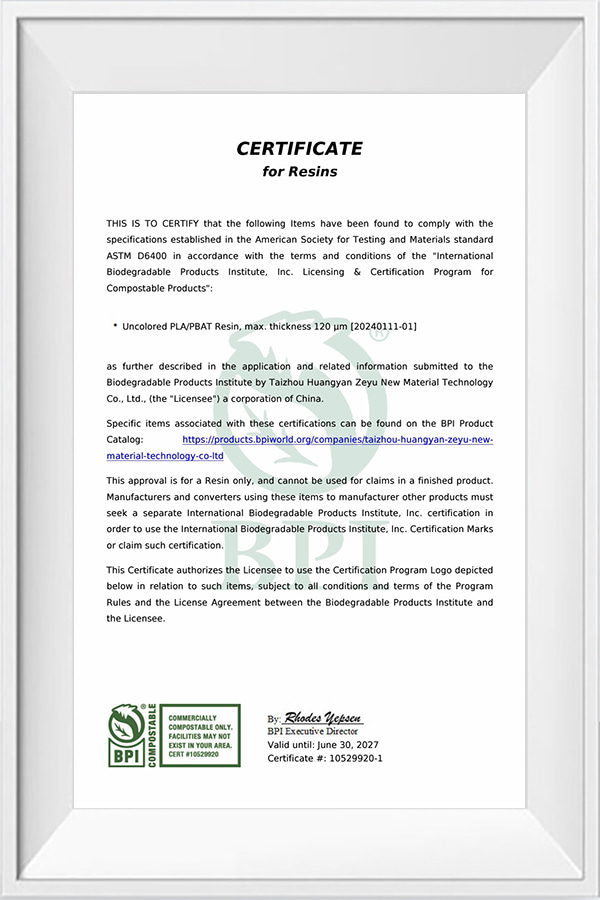

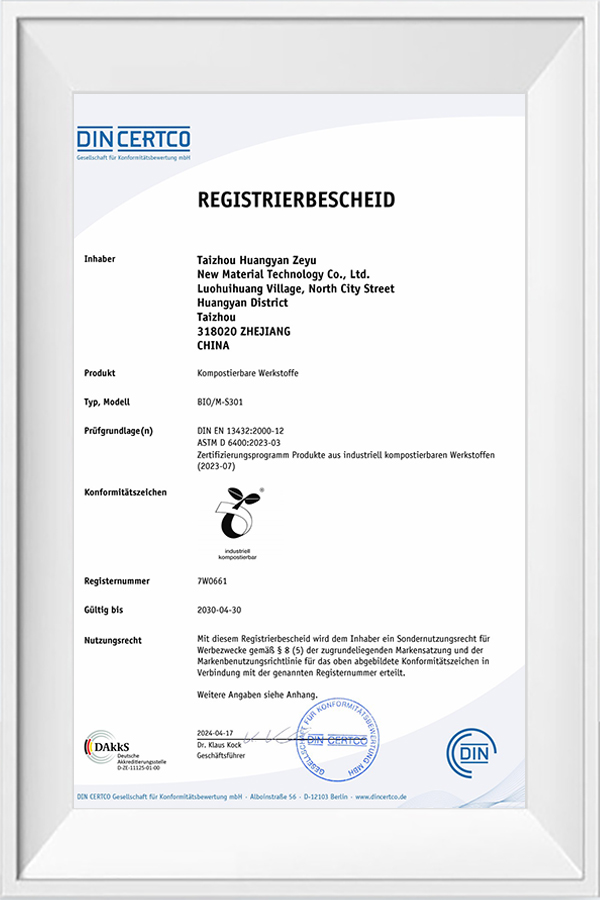

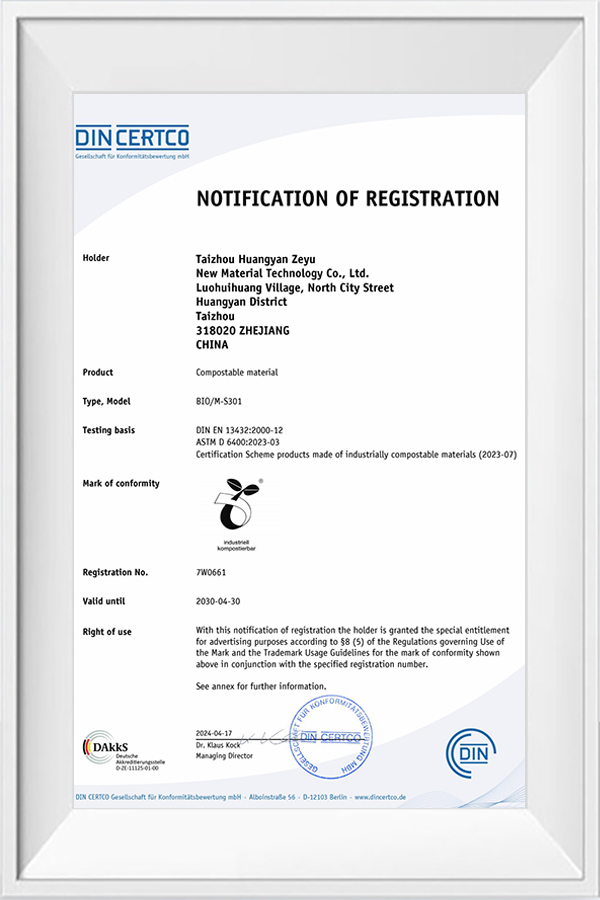

The fully biodegradable ultra-thin film materials produced by Huangyan Zeyu have significant competitive advantages in the market due to their unique lightness, high transparency, easy processing and environmental protection performance. First, the high transparency of the ultra-thin film ensures the visual beauty of the packaging and the product display effect, meeting the dual needs of the modern packaging industry for vision and texture; secondly, its excellent flexibility and mechanical strength enable it to perform well in processes such as film blowing, extrusion, and lamination on high-speed production lines, greatly improving production efficiency and product yield. In addition, the material itself has good weather resistance and tear resistance, which can meet the high standards of precision protection for electronic protective films. Most importantly, the material can be completely degraded in the natural environment, in line with strict environmental regulations and certification standards at home and abroad (such as GB/T19001-2016 and ISO9001:2015), helping companies achieve green packaging transformation and meet the urgent needs of consumers and the market for environmentally friendly products. The company continuously optimizes material performance and stabilizes the supply chain to ensure the balance of product quality, environmental protection and cost, further consolidates its leading position in the field of fully biodegradable ultra-thin films, and helps customers gain green competitive advantages.