What is PE+ST Polyethylene Resin?

PE+ST Polyethylene Resin is an environmentally friendly resin material based on polyethylene and combined with other renewable bio-based ingredients. Polyethylene, as a widely used plastic, is widely used in various packaging and industrial fields due to its excellent chemical stability, good low-temperature performance and high tensile strength. PE+ST Polyethylene Resin not only inherits these excellent properties of traditional polyethylene, but also reduces its carbon footprint and negative impact on the environment by introducing renewable raw materials, meeting the needs of green manufacturing and sustainable development.

The "ST" part of the resin usually represents bio-based or other renewable components blended with polyethylene, which enhance the environmental properties of the material and enable it to be better degraded or recycled during its life cycle. Compared with polyethylene from pure petrochemical sources, PE+ST resin uses renewable resources, generates lower greenhouse gas emissions during production and waste treatment, and has more obvious environmental benefits.

PE+ST Polyethylene Resin has good processing adaptability and is suitable for a variety of processes such as film blowing, injection molding and extrusion. It is widely used in the packaging industry, especially in the manufacture of degradable plastic bags, food packaging films and disposable products. At the same time, PE+ST resin is also suitable for agricultural packaging, medical packaging and daily consumer goods packaging, showing diverse application potential.

Why choose PE+ST Polyethylene Resin?

The main reason for choosing PE+ST polyethylene resin is that it has both the excellent properties of traditional polyethylene and meets environmental protection needs. It is an ideal material for the green transformation of the plastics industry.

PE+ST resin inherits the core properties of polyethylene: good chemical stability ensures that the material is not easy to degrade or deform in a variety of chemical environments, excellent low-temperature performance ensures that the packaging products can still maintain integrity and toughness in refrigerated or even frozen environments, and high tensile strength meets the packaging's requirements for puncture resistance and tear resistance.

Its raw materials are partially derived from bio-based renewable resources, which significantly reduces carbon emissions and environmental burdens, responding to increasingly stringent environmental regulations and consumer demand for sustainable products around the world. Products using PE+ST resin are more likely to obtain green certification and market recognition, and improve brand image.

PE+ST resin has good processing performance and is suitable for existing industrial equipment. Enterprises can achieve material upgrades and reduce transformation costs without significantly adjusting production lines.

In what fields are PE+ST polyethylene resins mainly used?

PE+ST polyethylene resins have been widely used in many fields due to their environmental protection properties and performance advantages.

The packaging industry is the largest application market for PE+ST resins. It is used to produce degradable plastic bags, food packaging films and disposable packaging products, replacing traditional non-degradable plastics and effectively reducing white pollution. Food packaging films must meet strict safety, barrier and preservation requirements. PE+ST resins perform well in these aspects and meet food grade standards.

In the field of agricultural packaging, PE+ST resins are used as ground films, agricultural films, etc., which not only meet the needs of agricultural production for material strength and weather resistance, but also achieve biodegradation after use and reduce soil pollution.

Medical packaging is also an important application direction for PE+ST resins, especially in the packaging of disposable medical supplies, which requires materials to have high hygiene and safety standards and certain environmentally friendly properties. PE+ST materials improve the environmental attributes of products while ensuring functionality.

How does Taizhou Huangyan Zeyu New Material Technology Co., Ltd. promote the development of the green plastic industry?

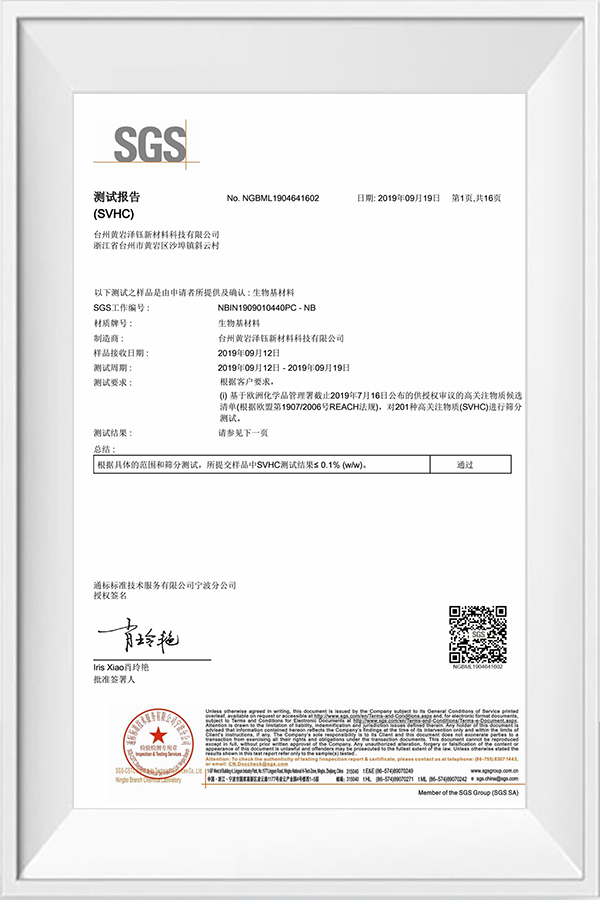

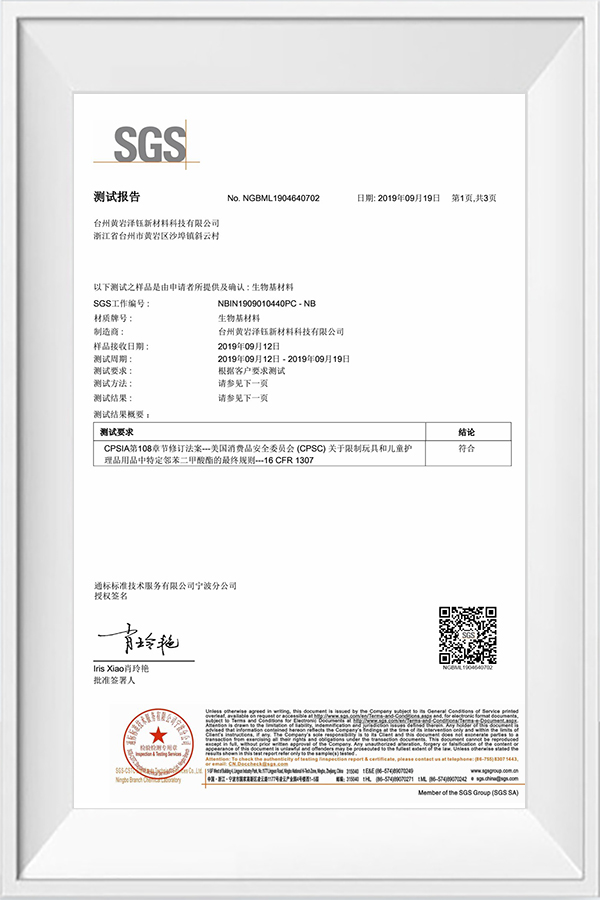

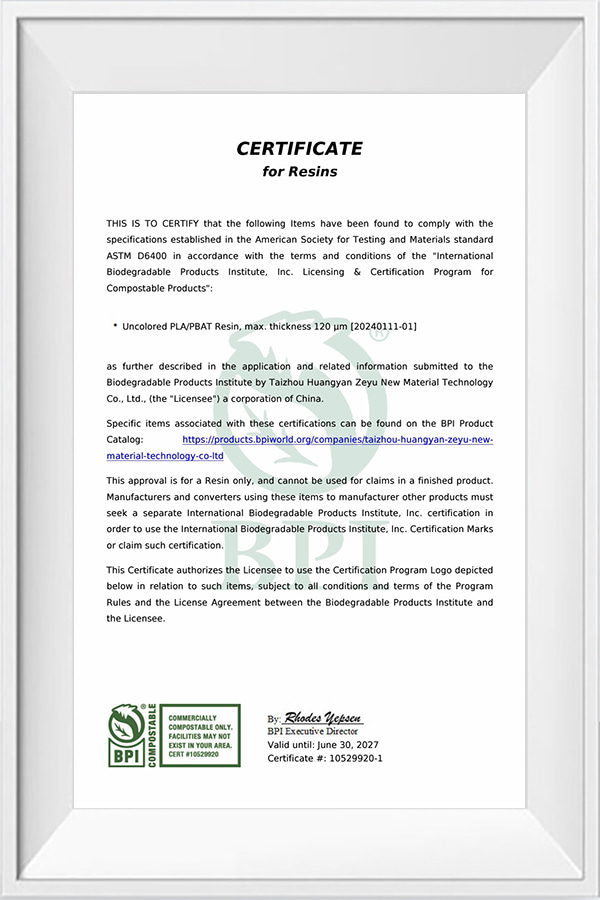

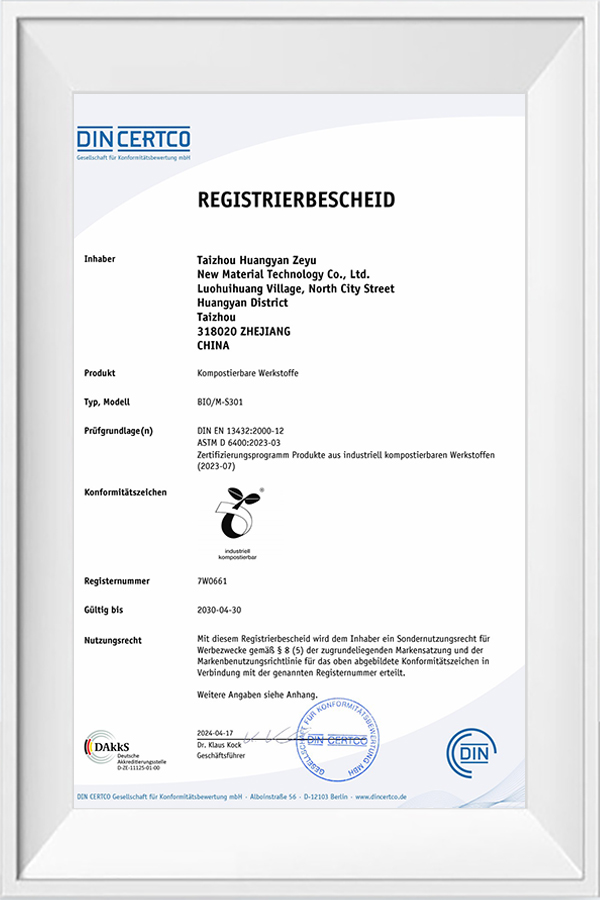

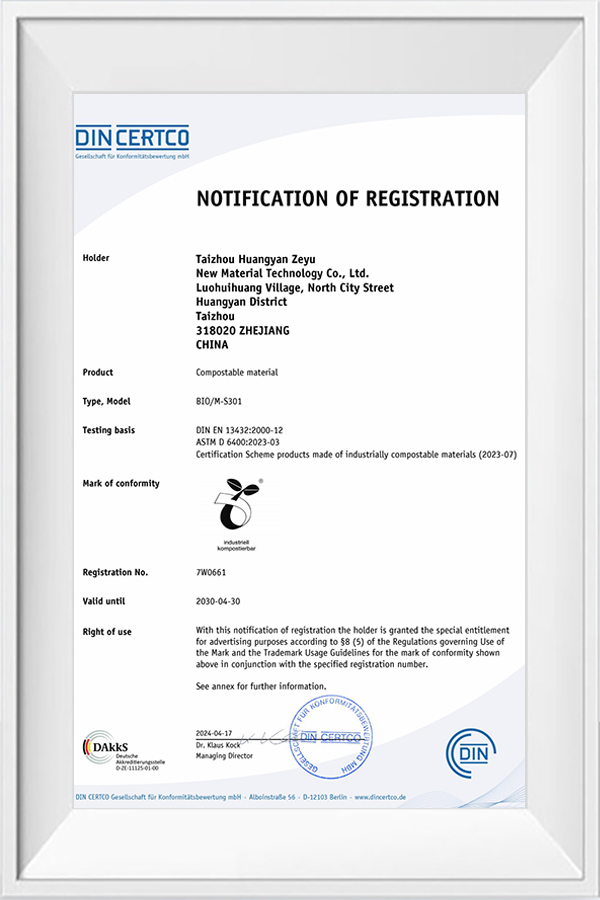

Taizhou Huangyan Zeyu New Material Technology Co., Ltd. is committed to the technical development, production and market promotion of fully biodegradable plastics and bio-based plastics, helping the plastics industry achieve green upgrades.

Taizhou Huangyan Zeyu New Material Technology Co., Ltd. has successfully developed a variety of fully biodegradable and bio-based plastic products based on a variety of bio-based materials such as PBAT, PLA, starch, etc. It has an independent R&D system and maintains close industry-university-research cooperation with well-known domestic universities and research institutions to ensure the advancement of technology and high quality of products.

Taizhou Huangyan Zeyu New Material Technology Co., Ltd.'s products not only meet domestic market demand, but are also exported to European Union countries, demonstrating international competitiveness and responsiveness to global green manufacturing trends. Through technological innovation and market promotion, Zeyu New Materials is actively promoting the popularization and application of environmentally friendly materials such as PE+ST polyethylene resin, contributing to the sustainable development of plastic products.