What is PP+ST Polypropylene Resin?

PP+ST Polypropylene Resin is an environmentally friendly resin material based on traditional polypropylene (PP) and combined with other renewable resources. Its core feature is to combine PP with bio-based renewable ingredients to form a new material that not only inherits the high strength, heat resistance and chemical corrosion resistance of traditional polypropylene, but also has a lower carbon footprint and less environmental impact.

Traditional polypropylene is widely used in the plastics industry for its excellent mechanical properties, heat resistance and chemical stability, but its raw materials mostly rely on petrochemical resources. PP+ST polypropylene introduces bio-based raw materials, such as plant extracts or other renewable ingredients, while maintaining or even improving the material performance, greatly reducing the burden on the environment. This is not only in line with the current global trend of green manufacturing and sustainable development, but also provides an important path for the environmental protection upgrade of the plastic materials industry.

PP+ST polypropylene resin has a stable structure and can adapt to a variety of processing technologies, such as injection molding, blow molding and extrusion, and it shows good durability and biodegradation potential during production and use. Therefore, this type of material is regarded as an environmentally friendly alternative to traditional PP.

Why choose PP+ST polypropylene resin?

The reason for choosing PP+ST polypropylene resin is mainly reflected in its advantages of both performance and environmental protection:

High performance: PP+ST resin maintains the mechanical strength, heat resistance and chemical corrosion resistance of traditional polypropylene, ensuring the structural safety and long-term stability of the product.

Environmental advantages: Made of bio-based renewable raw materials, it reduces carbon emissions and environmental pollution, and is in line with the global green manufacturing and circular economy concepts. Compared with pure petrochemical plastics, PP+ST significantly reduces dependence on fossil resources.

Diversified applications: The material is suitable for a variety of processing technologies and can meet the high quality requirements of plastic products in different industries.

Economic benefits: Because its raw materials contain renewable resources and have good processing performance, the overall cost is more competitive than other high-end environmentally friendly materials, and it is suitable for large-scale industrial applications.

Application fields and classification of PP+ST polypropylene resin

PP+ST polypropylene resin is widely used in many industries due to its performance advantages and environmental protection characteristics, which can be mainly divided into the following categories:

Packaging industry: As an environmentally friendly resin, PP+ST is widely used in the production of degradable plastic bags, food packaging films and disposable packaging products. This type of material not only meets the requirements of packaging for strength and flexibility, but also can be biodegraded after use, reducing plastic pollution and conforming to the concept of green consumption.

Automotive industry: In the field of automobile manufacturing, PP+ST is used as a material for automobile shells, interior parts and other structural parts to replace traditional petrochemical plastics. Its high strength and heat resistance ensure the stability of automobile parts in complex environments, while reducing the carbon footprint of plastics to achieve environmental protection upgrades in automobile manufacturing.

Home appliances and electronic products: PP+ST is widely used in the manufacture of housings for home appliances and electronic products. It provides excellent heat and chemical corrosion resistance, ensuring the safety and durability of equipment, while giving home appliances green environmental protection attributes and enhancing the image of corporate social responsibility.

How does Taizhou Huangyan Zeyu New Material Technology Co., Ltd. promote innovation and development in the green plastics industry?

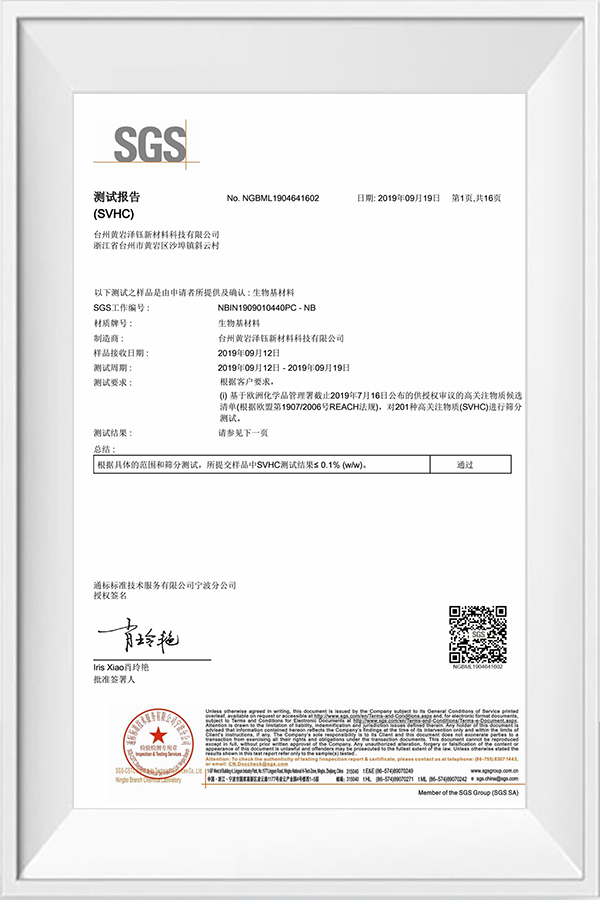

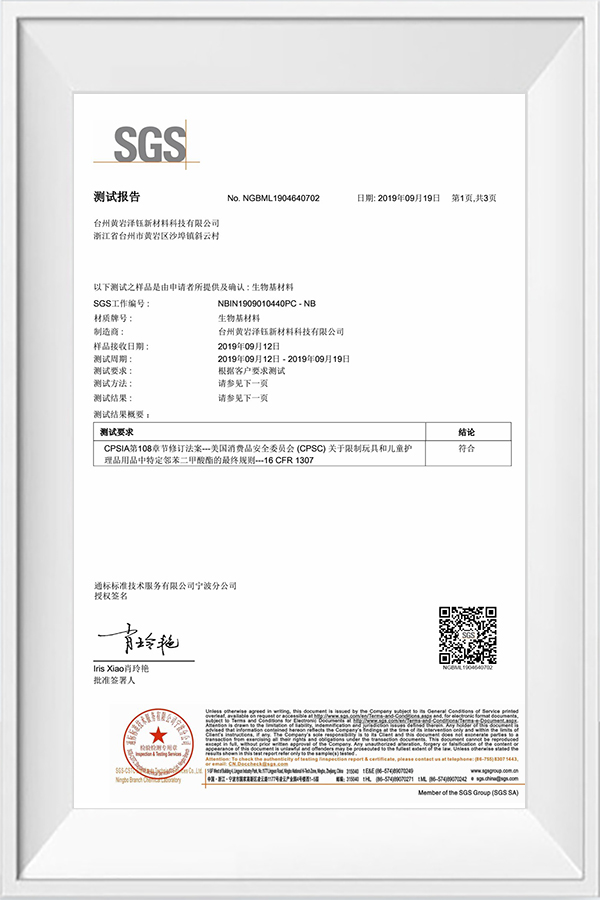

Since its establishment, Taizhou Huangyan Zeyu New Material Technology Co., Ltd. has been committed to promoting the innovation and development of the green plastics industry. The company focuses on the technical research and development, production and promotion of fully biodegradable plastics and bio-based plastics. With advanced technical strength and good industrial chain cooperation, it has achieved remarkable results in the field of environmentally friendly materials.

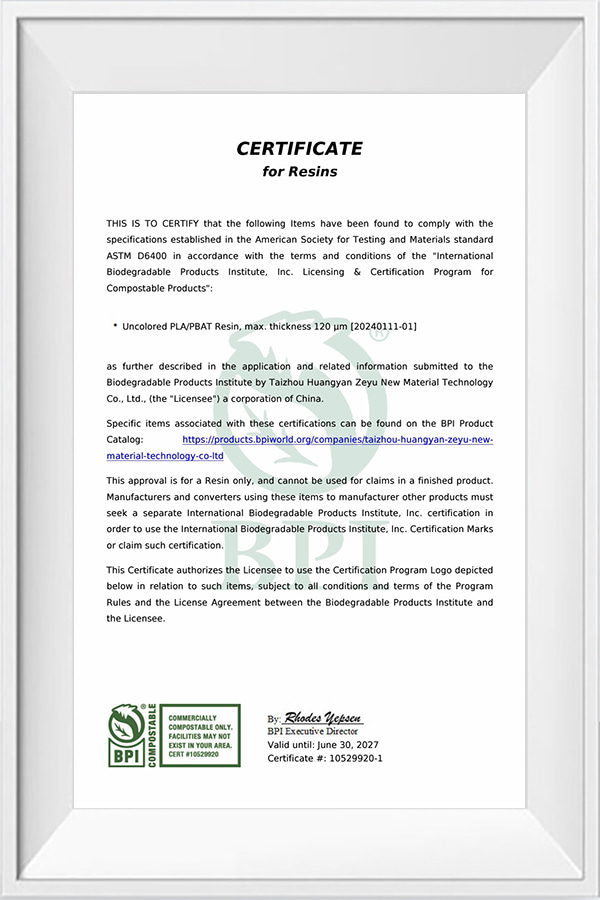

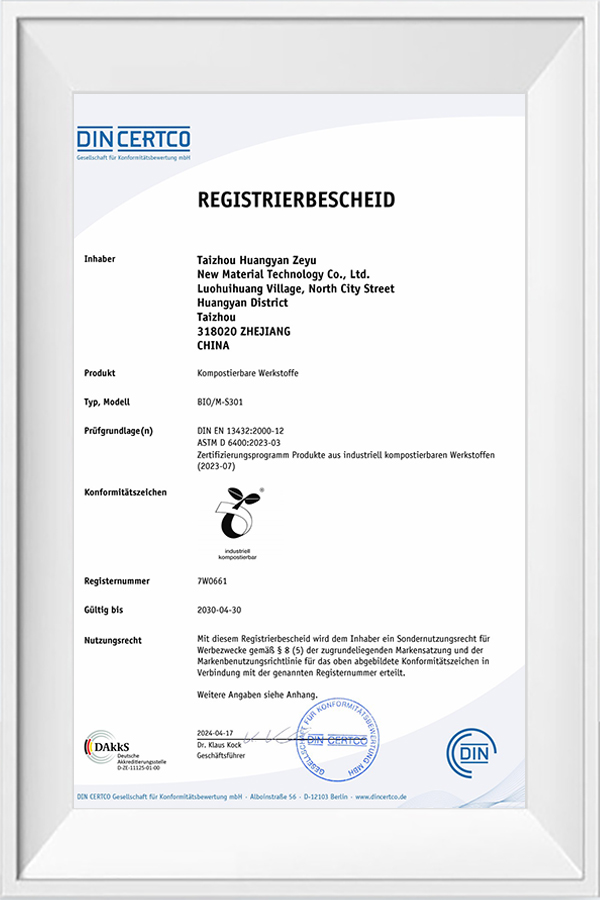

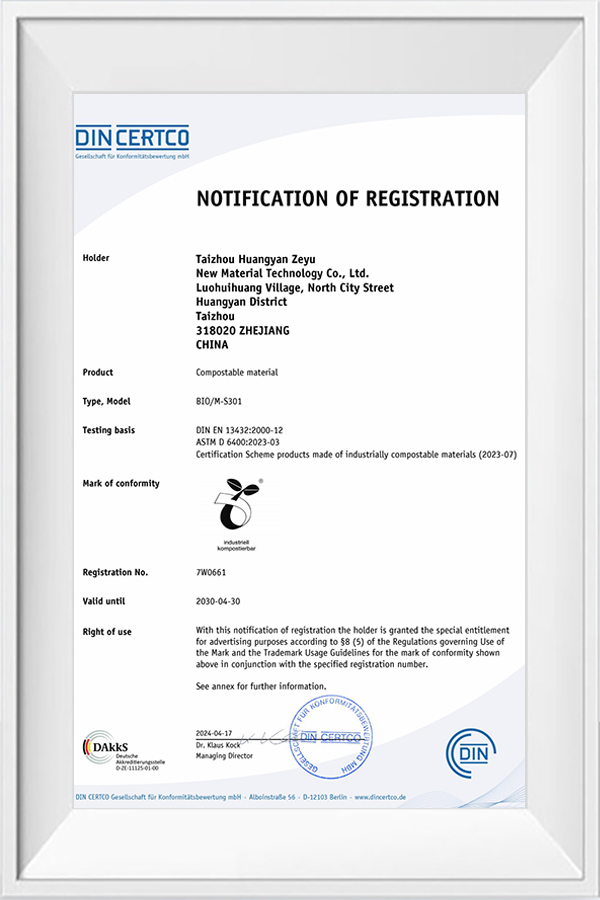

The core technology of Zeyu New Materials focuses on the development of bio-based plastic products based on renewable resources such as PBAT, PLA, starch, etc. Through precise research and development and experiments, Zeyu New Materials has successfully transformed these bio-based materials into widely applicable environmentally friendly plastics, which have the high strength, heat resistance and chemical stability of traditional plastics, and have good biodegradability at the end of their life cycle, reducing the negative impact of plastic waste on the environment.

Zeyu New Materials also continuously improves its technical research and development capabilities through close cooperation with well-known domestic universities and research institutions to ensure that it is in the leading position in the field of biodegradable plastics. The company now has an independent R&D system and has developed a number of fully biodegradable products suitable for different fields, which have been widely recognized by the market.

Zeyu New Materials has established a strategic partnership with domestic film blowing companies, and through technology promotion and market expansion, it has promoted the widespread application of bio-based plastics in packaging, automobiles, home appliances, etc. As a promoter of green manufacturing, Zeyu New Materials not only helps customers achieve environmental protection upgrades for their products, but also makes positive contributions to the sustainable development of the plastics industry.