Environmental protection and performance: the core advantage of Bio-friendly lunch boxes are environmentally friendly

The materials used in Bio-friendly lunch boxes are environmentally friendly, such as polybutylene adipate/terephthalate, polylactic acid and modified starch, are the mainstream choices in the field of green packaging materials today. These materials not only come from renewable resources, reducing dependence on petroleum-based materials, but also have excellent biodegradability. Under certain conditions, these environmentally friendly materials can be completely degraded into carbon dioxide and water within 3 to 6 months through the action of microorganisms, without any harmful substances remaining, and without secondary pollution, truly realizing "from nature to nature".

Compared with traditional plastic lunch boxes such as polypropylene or polystyrene, the degradation cycle of traditional plastics in the natural environment can be as long as hundreds of years. They are easily broken into microplastics and stay in the soil and water for a long time, and finally return to the human body through the food chain, causing health risks. The bio-environmentally friendly lunch box cuts off the generation path of microplastics from the source, providing a safer guarantee for the ecological environment, and is the preferred solution for sustainable packaging in the future.

In terms of functional performance, modern Bio-friendly lunch boxes are environmentally friendly have achieved practicality comparable to or even surpassing that of traditional plastic lunch boxes through advanced material modification and molding technology. For example, it can maintain good physical stability in high temperature environments. Even if it is heated for a short time or used in a microwave oven in an environment above 80°C, it will not soften, deform or release harmful gases, ensuring food safety. At the same time, its good oil resistance, water resistance and sealing properties enable it to effectively prevent food leakage in practical applications and meet the packaging needs of a variety of dishes such as hot soups and fried foods.

This material also has advantages in visual experience: the lunch box has a smooth surface, delicate feel and natural color. It not only has good visual beauty, but also can be printed with brand logos and environmentally friendly labels through screen printing, thermal transfer and other methods, which is convenient for merchants to carry out differentiated customization and green publicity, and further enhance the brand's image and identity in the minds of consumers.

Wide application: Promote green transformation of the catering industry

Bio-friendly lunch boxes are environmentally friendly have rapidly emerged in various scenarios due to their environmental protection and functionality, promoting the entire industry chain to upgrade in a sustainable direction.

In the catering service industry, large chain fast food brands, catering companies, shopping malls and food courts have taken the lead in using biodegradable lunch boxes to replace traditional plastic boxes, which not only meets regulatory requirements, but also demonstrates their social responsibility and green operation concept. Especially today when consumers are paying more and more attention to "carbon footprint" and corporate environmental protection commitments, the use of environmentally friendly packaging has become an important part of brand image building.

In the field of food delivery platforms, platforms such as Meituan and Ele.me have gradually established a classification and recommendation mechanism for environmentally friendly packaging, and have given incentives such as green labels and exposure priority to merchants who use environmentally friendly lunch boxes. The use of environmentally friendly lunch boxes not only helps the platform meet regulatory requirements, but also enhances users' recognition of the platform's green operation concept, forming a benign interaction.

In family life scenarios, more and more families tend to choose environmentally friendly lunch boxes when preparing their own lunch boxes, picnics or daily storage. Compared with traditional plastic or foam lunch boxes, biological environmentally friendly lunch boxes are not only safe and non-toxic, but also do not need to worry about disposal problems after use. They can be directly discarded and degraded, which greatly facilitates the green life practice of family users.

In educational and medical institutions, environmentally friendly lunch boxes are widely used in places with high hygiene standards such as student canteens and hospital wards due to their non-toxic, degradable and high safety characteristics, reflecting the care for the dual protection of health and environment of vulnerable groups (such as students and patients).

The widespread implementation of bio-friendly lunch boxes in various usage scenarios not only meets the functional use needs, but also promotes the green transformation of the entire chain of the catering industry from raw materials, production links to the end-use terminal.

Zeyu New Material's technical leadership and industrial layout

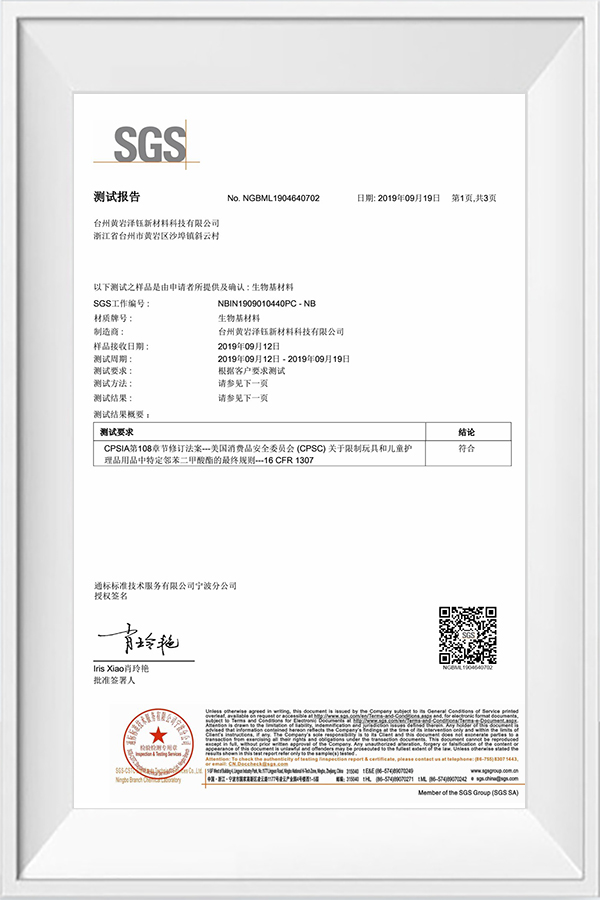

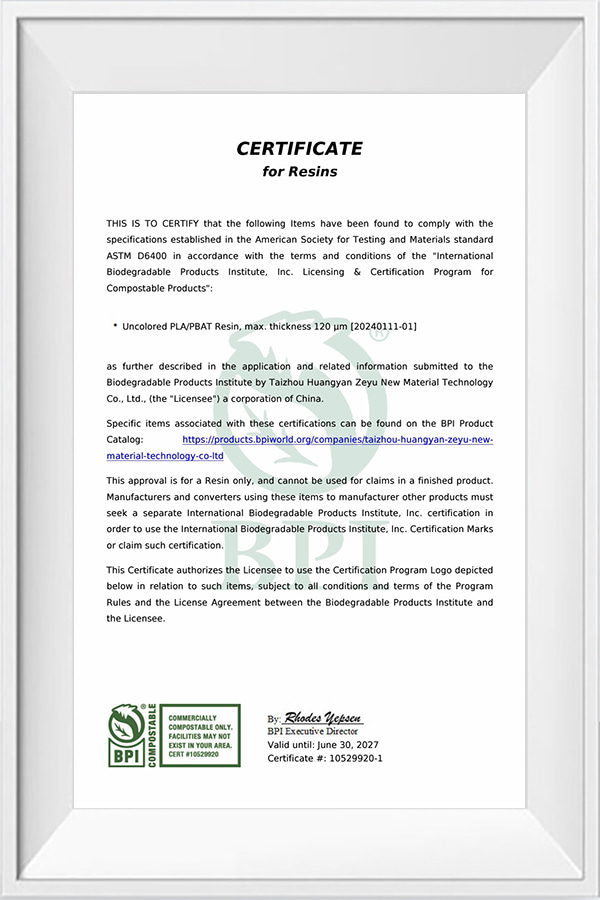

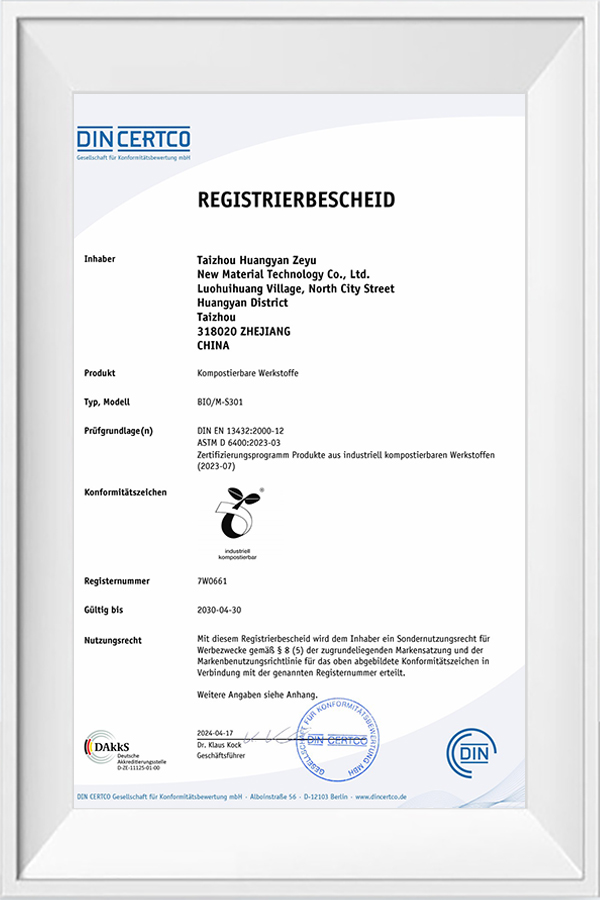

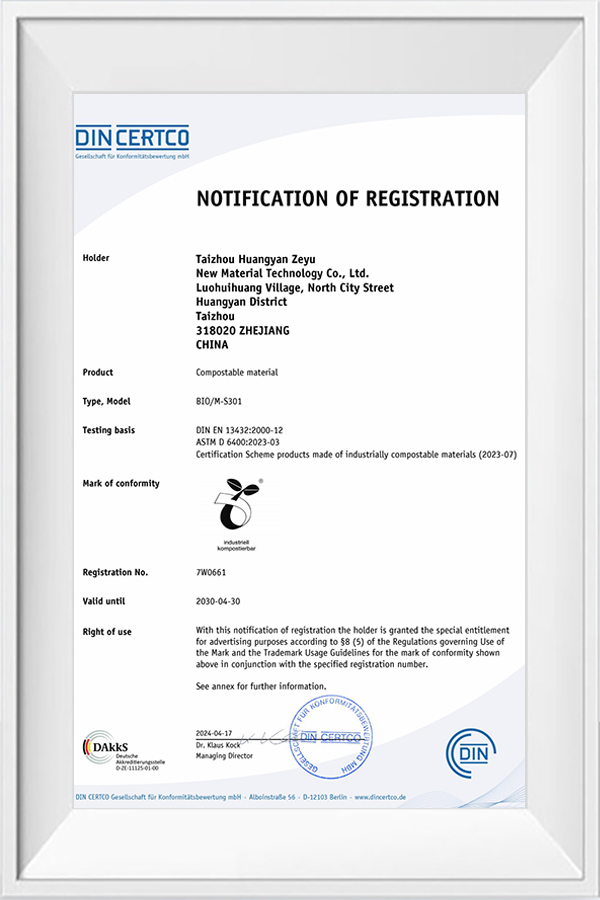

As a benchmark enterprise in the field of fully biodegradable materials in China, Taizhou Huangyan Zeyu New Material Technology Co., Ltd. has always been committed to the research and development, innovation and promotion of green material technology. The company has been deeply involved in the field of biodegradable polymer materials for more than ten years, and has built an independent system for the entire process from raw material research and development, product design, equipment molding to quality control, with strong comprehensive supporting capabilities.

In terms of raw material technology, Zeyu Technology has mastered the core formula of blending and modification of basic materials such as PBAT and PLA. Aiming at the specific requirements of environmentally friendly lunch boxes for heat resistance, toughness, molding and other indicators, it has developed a variety of special-grade degradable materials, which not only improves the comprehensive performance of the products, but also optimizes production efficiency and molding accuracy.

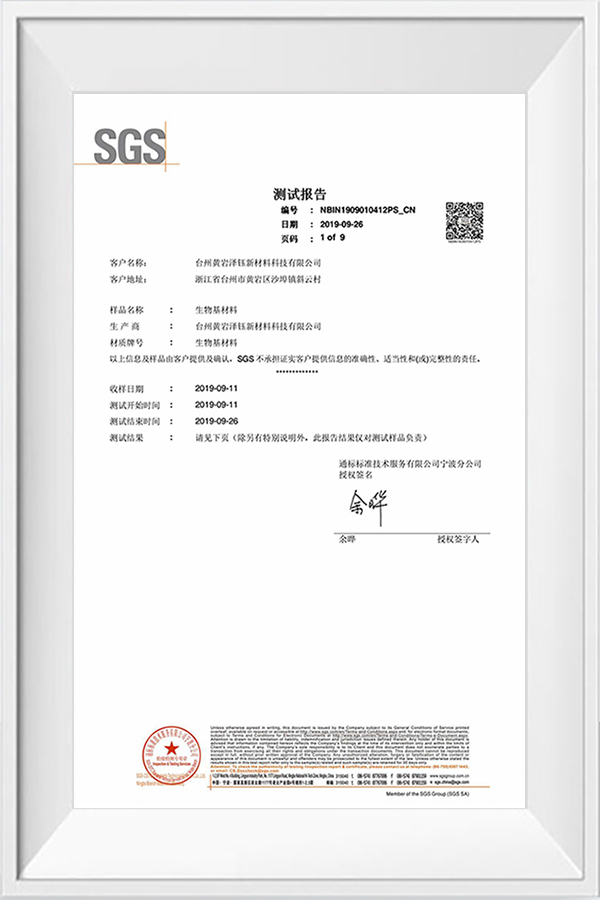

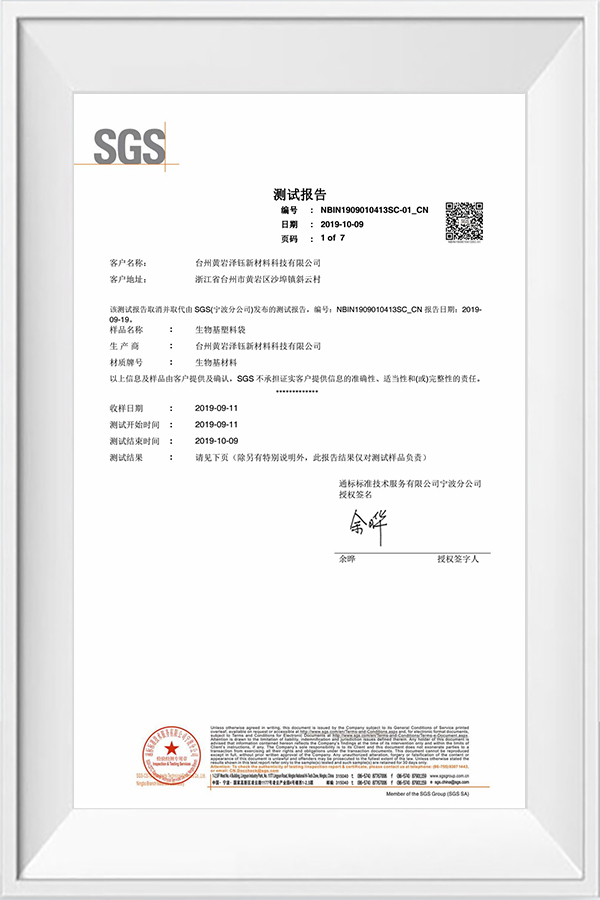

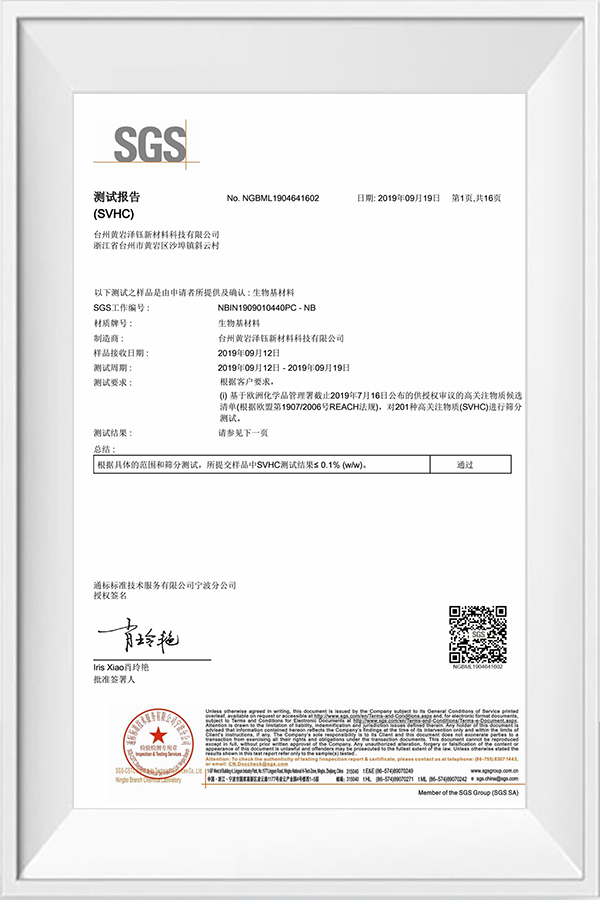

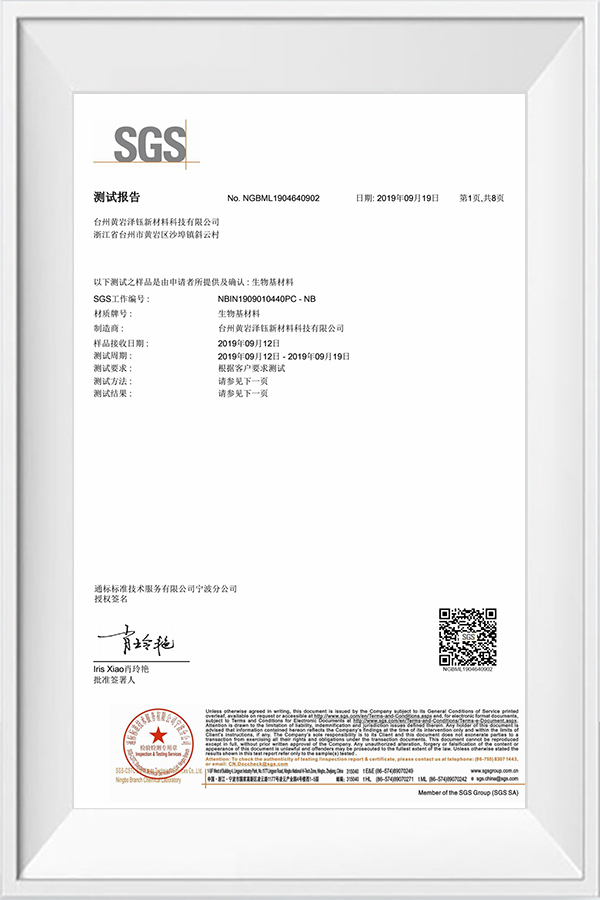

In terms of product design, the company has developed a variety of series and specifications of environmentally friendly lunch box products, covering a variety of structural forms from single-grid, double-grid to multi-grid, sealed, nested, etc., which widely meet the diverse needs of different dishes and different application scenarios. All products have passed ISO9001:2015 quality management system certification and passed industry third-party testing in terms of heat resistance, sealing, safety, etc. In the production and manufacturing process, the company is equipped with multiple advanced injection molding machines, hot pressing molding equipment and mold systems, with the ability to produce tens of millions of sets of environmentally friendly lunch boxes annually, ensuring short delivery cycles and strong product consistency. At the same time, Zeyu Technology actively promotes green production processes, optimizes energy use and raw material losses, and minimizes carbon emissions and environmental impacts during production. In terms of R&D mechanisms, the company attaches great importance to the "industry-university-research" collaboration with universities and scientific research institutions, and continuously promotes breakthroughs in the performance of environmentally friendly materials through cooperation. For example, by modifying the structure of the PBAT-PLA system, its thermal stability and edge strength under high temperature and high pressure are improved, making it more suitable for fast food packaging and high-temperature food application scenarios.