From "plastic ban" to "plastic replacement": the straw revolution is urgent

Traditional plastic straws are mostly made of polymer synthetic materials such as polypropylene or polystyrene. These plastic raw materials have the advantages of good formability, low cost, moderate strength, waterproof and oil-proof, etc., suitable for mass production, and widely used in the field of disposable beverage packaging. However, this type of polymer material is a non-renewable resource based on petroleum, and its chemical structure is stable and difficult to be degraded by microorganisms under natural conditions. Materials such as polypropylene and polystyrene are almost "non-degradable" in nature. Even if they are broken under the action of sunlight, weathering, etc., they are only "physically broken" and are still tiny plastic particles rather than truly degraded. Straws are small, frequently used, and randomly discarded disposable plastic products, which are often difficult to be effectively covered by the recycling system. It is estimated that more than 500 million disposable straws are used in the United States alone each year, and the number used worldwide is in the billions every day. These plastic straws are very easy to enter the natural environment, blown away by the wind, washed into drains by rain, and eventually flow into rivers and oceans, becoming an important part of marine plastic pollution.

Bio-friendly straws based on materials such as polybutylene adipate/terephthalate, polylactic acid, and modified starch have emerged. As a green alternative that is fully degradable or partially bio-based, they can decompose into water and carbon dioxide under certain conditions while ensuring the user experience, achieving "no trace after use".

Product advantages: environmental protection, safety, and uncompromised experience

The continuous breakthroughs in technology and materials of modern Bio-friendly straws have made them close to or even surpass traditional plastic straws in terms of performance, fully adapting to daily beverage consumption needs:

1. Completely degradable, green return to nature

Bio-friendly straws are made of bio-based or fully degradable materials such as PBAT and PLA. In soil, seawater or industrial composting environments, microorganisms can decompose them into water and carbon dioxide within a few months to a year without leaving any harmful residues. This feature makes it particularly popular in the context of "carbon neutrality" and meets the standards for green supply chain construction.

2. Both strength and toughness, good user experience

After material modification and production process optimization, environmentally friendly straws have reached or exceeded traditional straws in terms of suction, bendability, and crack resistance. Whether it is hot or cold drinks, carbonated drinks, or thick drinks such as milkshakes and smoothies, they can adapt stably without deformation, softness, or rebound, ensuring a good drinking experience.

3. Wide temperature resistance, adaptable to multiple scenarios

High-quality biological environmentally friendly straws can withstand temperatures usually between -10℃ and 70℃, and some products can even withstand higher temperatures for a short time. This makes it widely used in multiple scenarios such as cold drink shops, hot drink cafes, milk tea chains, and takeaway platforms.

4. Safe and non-toxic, food-grade guarantee

Biological environmentally friendly straws do not contain harmful additives such as plasticizers and bisphenol A, and meet food-grade safety standards. It is safer when in direct contact with the mouth, especially suitable for special groups such as children and pregnant women.

5. Customizable printing to enhance brand recognition

PLA and PBAT materials have good printing adaptability. Enterprises can customize LOGO, environmental protection logo or activity slogan on straws or packaging according to brand needs, which will enhance consumers' environmental protection recognition and help brand promotion.

Multi-scenario application: Leading the green transformation of the beverage industry

The wide applicability of Bio-friendly straw makes it the preferred green packaging for many catering and beverage formats:

1. Beverage chain and milk tea industry

Brands such as Cha Baidao, Heytea, and Nayuki's Tea took the lead in piloting the use of PLA straws to respond to the call for environmental protection. Consumer acceptance continues to increase, and environmentally friendly straws have gradually become a standard configuration for brands. Some brands even obtain green points by "actively rejecting plastic straws" to encourage environmentally friendly consumption.

2. Takeaway and fast food platforms

In the context of Meituan, Ele.me and other platforms actively promoting green packaging, more and more catering merchants have begun to purchase biodegradable straws as standard for packaged beverages, which not only meets regulatory requirements but also demonstrates an image of environmental responsibility.

3. Coffee and chain convenience scenarios

Coffee brands such as Starbucks and Luckin Coffee are replacing traditional plastic straws with paper straws or PLA straws, but paper straws are criticized for being soft and easy to collapse. Bio-friendly straws take into account both environmental protection and experience in this regard, becoming an important solution to optimize the user's taste experience.

4. Banquets, exhibitions and public service scenarios

Disposable beverage services are frequent in various exhibitions, wedding banquets, hotel buffets and other occasions. The use of degradable straws can significantly reduce the total amount of plastic waste, reflect the green concept and social responsibility of the organizer, and improve the overall service quality.

Taizhou Huangyan Zeyu New Material Technology Co., Ltd.: A technical leader in bio-friendly straw solutions

Taizhou Huangyan Zeyu New Material Technology Co., Ltd., as a leading domestic biodegradable material application company, has always focused on the research and development and promotion of fully biodegradable plastics and bio-based plastics. With the mission of "environmentally friendly materials to help a sustainable future", the company is committed to creating a high-performance, low-environmental-load alternative product system.

Relying on a combination of PBAT, PLA, modified starch and other materials, Taizhou Huangyan Zeyu New Material Technology Co., Ltd. independently develops and mass-produces multiple specifications and models of bio-friendly straw products, covering a wide range of:

Straight straws: suitable for daily beverages, with a full range of sizes;

Telescopic straws: easy to carry, suitable for travel and portable scenarios;

Large-caliber straws: specially designed for thick drinks such as milkshakes and pearl milk tea;

Oblique-mouth straws: used for sucking jelly, sucking bagged drinks and other scenarios.

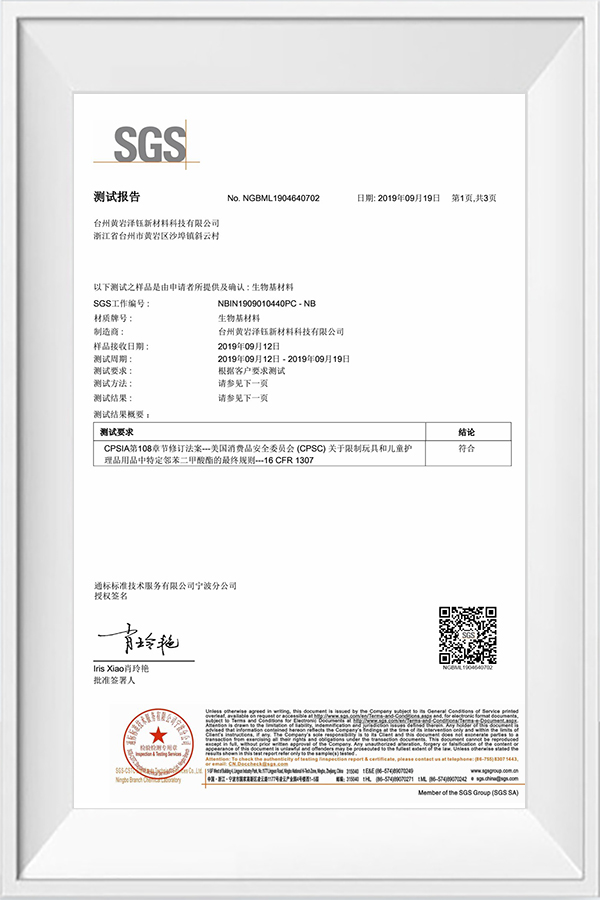

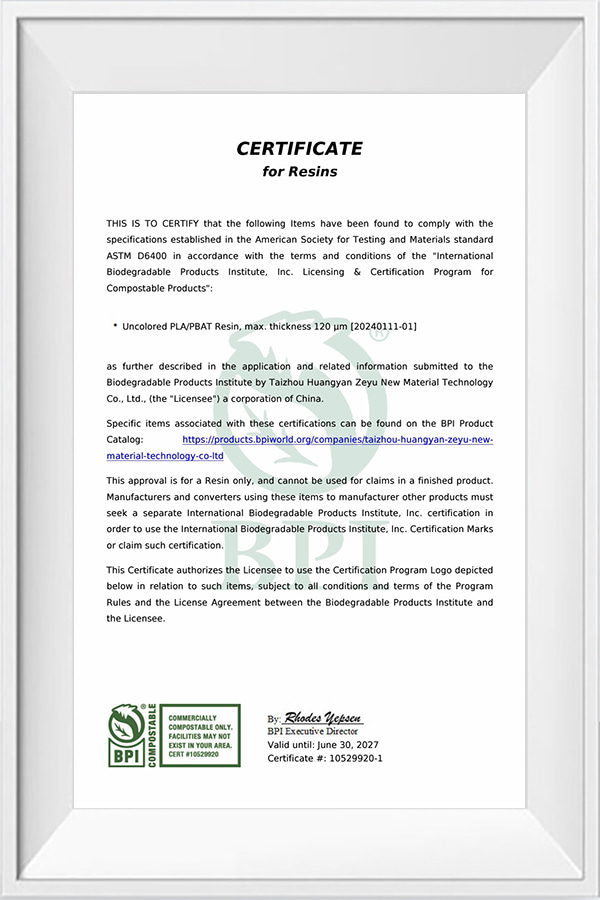

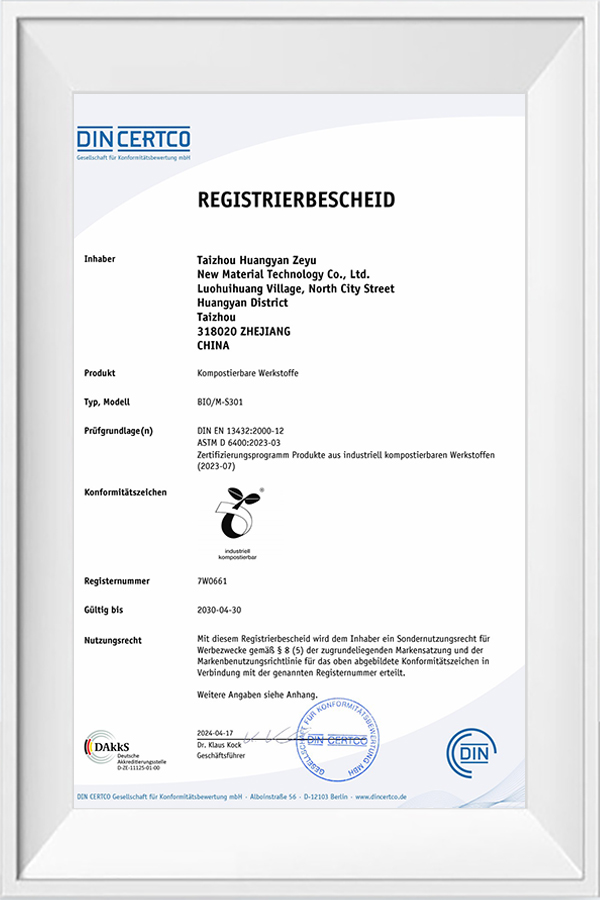

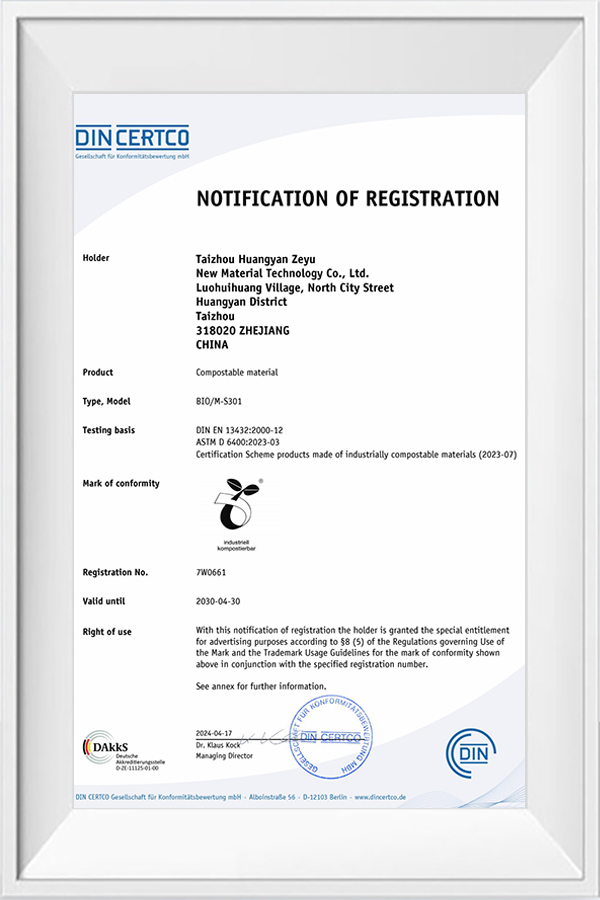

The company has a complete raw material modification system, precision molding equipment and strict quality control processes to ensure the stable performance of straws in various beverage environments, and has passed the GB/T19001-2016 and ISO9001:2015 dual quality management system certifications, with reliable product performance and controllable quality. Taizhou Huangyan Zeyu New Material Technology Co., Ltd. attaches great importance to collaborative innovation between industry, academia and research, and has joined forces with many scientific research institutes to promote the performance optimization and cost reduction and efficiency improvement strategies of new biodegradable materials to enhance industry competitiveness.