What is Fully Biodegradable Film? Why is it regarded as an environmental revolution in the plastic film industry?

Fully Biodegradable Film is an environmentally friendly film made of fully biodegradable materials, which are usually derived from bio-based resources or degradable synthetic polymers such as PBAT, PLA and starch. Compared with traditional petroleum-based plastic films, fully biodegradable films can be decomposed into water, carbon dioxide and biomass by microorganisms in the natural environment, leaving no residue and no toxicity, and having almost no negative impact on soil, water bodies and ecosystems.

This film not only has the excellent properties of traditional plastic films, such as high strength, good flexibility, high transparency and stable heat sealing performance, but also solves the problem that traditional plastics are difficult to degrade and cause "white pollution", and truly realizes green environmental protection throughout the life cycle from production to disposal. For this reason, the global demand for fully biodegradable films continues to grow, becoming an important alternative material in the fields of green packaging, agricultural films, medical packaging, etc.

What are the main categories and applications of Fully Biodegradable Film? How to meet the environmental protection needs of different fields?

Fully biodegradable films can be divided into multiple types according to their uses and performance requirements, suitable for different industries and scenarios:

1. Biodegradable films for food packaging: This type of film requires high food safety level, no odor, excellent barrier properties and good transparency, and is used for fresh fruits and vegetables, frozen foods, fast food box sealing films, etc. The use of fully biodegradable films can effectively extend the shelf life of food, and quickly degrade after use to avoid the accumulation of food packaging waste in the environment.

2. Biodegradable films for agriculture: including ground films, seedling bed films, vegetable covering films, etc. Traditional PE ground films cause soil pollution due to the difficulty of recycling and long decomposition cycle. After use, fully biodegradable ground films can be quickly decomposed into harmless substances by microorganisms in the soil, which not only protects the soil ecology, but also reduces the cleaning costs of farmers, and helps the development of green agriculture.

3. Degradable films for industrial and logistics packaging: This type of film is used for product protective packaging, container films, stretch films, etc. Industrial-grade fully biodegradable film has mechanical strength and tensile properties. While ensuring product safety during transportation, it quickly degrades after being discarded, complies with international environmental regulations, and is suitable for export markets.

How does Taizhou Huangyan Zeyu New Material Technology Co., Ltd. use sustainable raw materials to maximize the environmental value of fully biodegradable films?

Taizhou Huangyan Zeyu New Material Technology Co., Ltd. always adheres to the concept of sustainable materials and is committed to using fully biodegradable and bio-based plastics to produce environmentally friendly films. The raw materials selected by the company not only reduce dependence on fossil fuels, but also ensure the natural degradation ability of the materials, truly realizing an ecological closed loop from "green source" to "green recycling".

Green and environmentally friendly raw materials: using raw materials such as plant-based lactic acid, plant starch and degradable polyester, which have both renewability and excellent degradation performance, significantly reducing carbon emissions and energy consumption in the production process.

Environmental protection throughout the product life cycle: from raw material collection, production and manufacturing, packaging and transportation, to use and final degradation, each link strictly controls environmental impact. The fully biodegradable film produced by Taizhou Huangyan Zeyu New Material Technology Co., Ltd. can be completely degraded in soil or industrial composting environment after its service life, avoiding the environmental pollution and resource waste of traditional plastics.

Technological innovation helps improve performance: Through continuous R&D investment, Taizhou Huangyan Zeyu New Material Technology Co., Ltd. continuously optimizes the film formula and processing technology, improves the mechanical strength, flexibility and heat sealing performance of the film, making the product not only environmentally friendly, but also able to meet strict industrial and consumer needs.

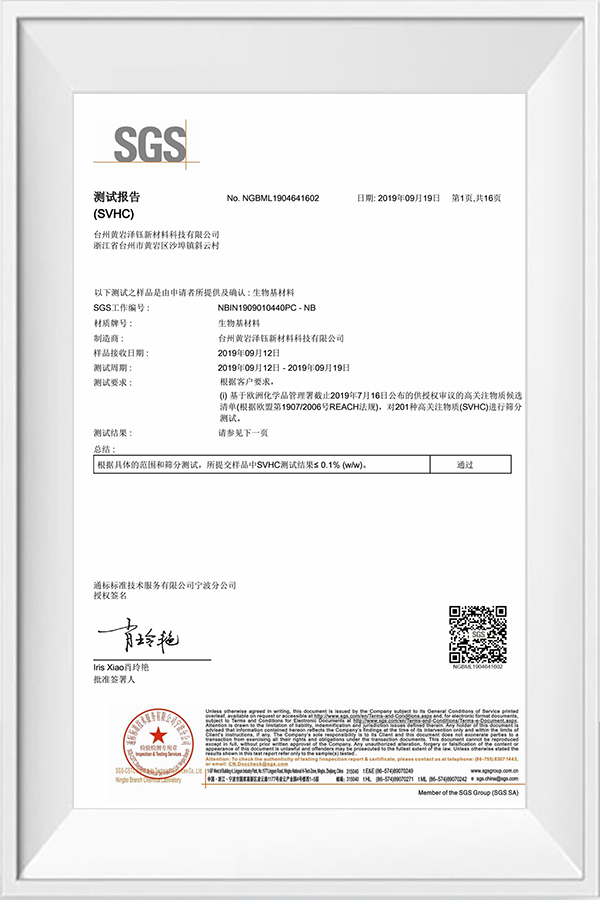

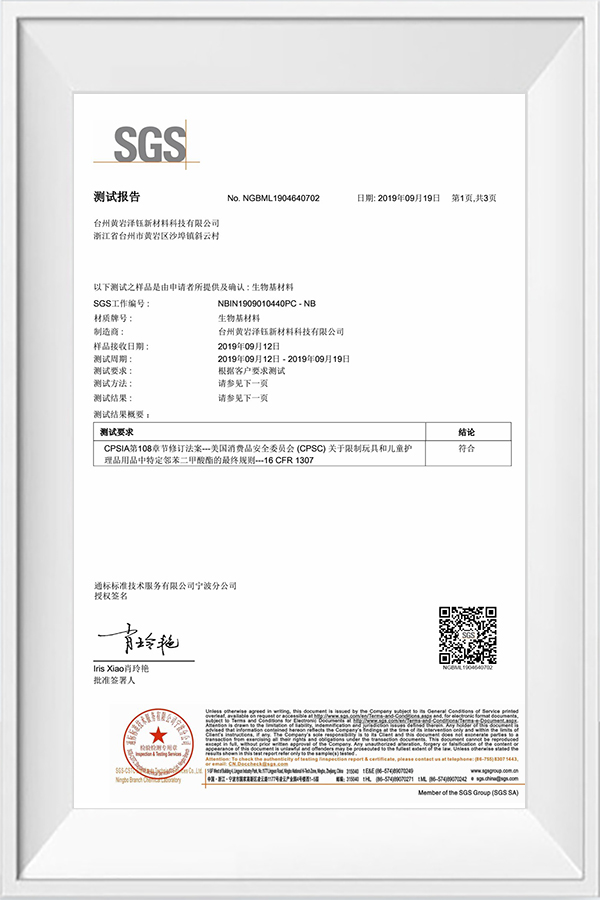

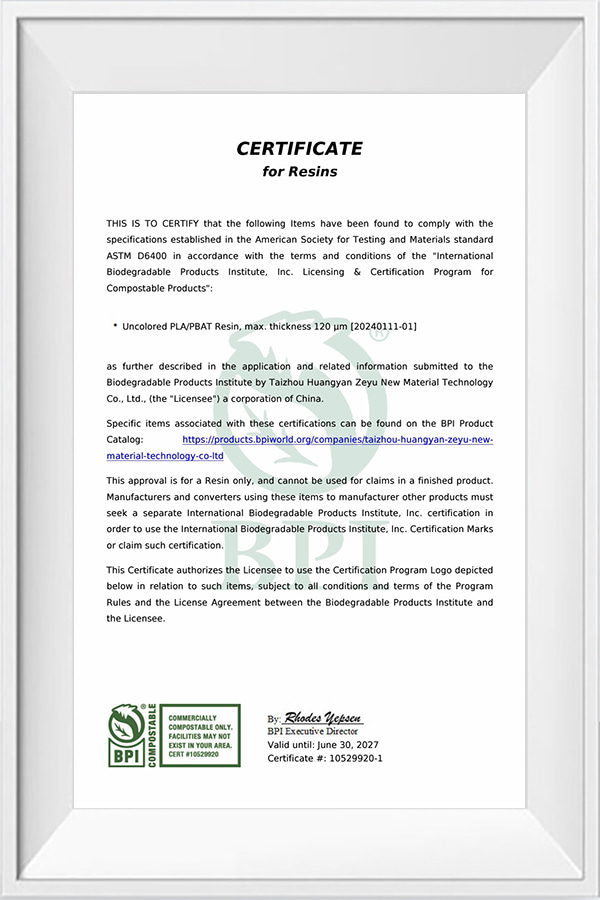

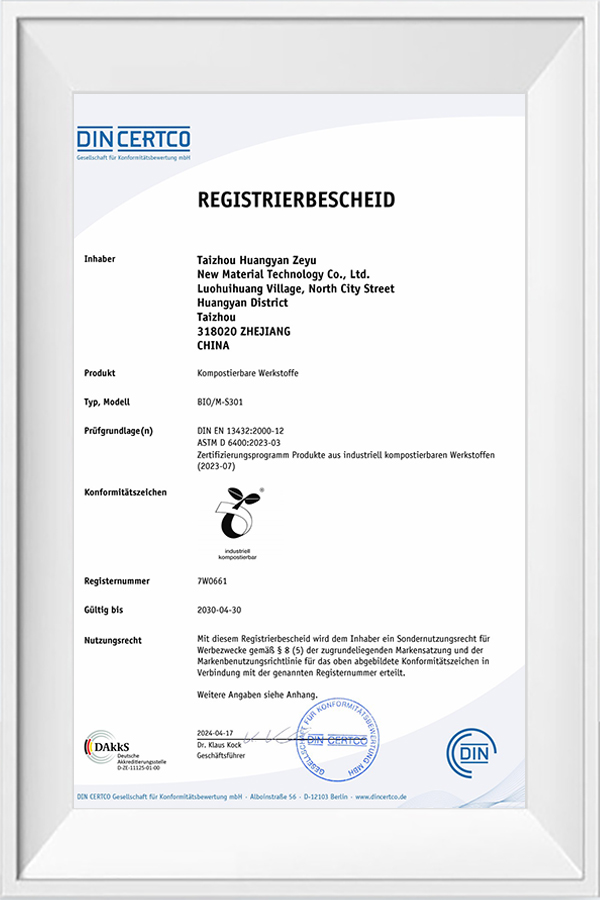

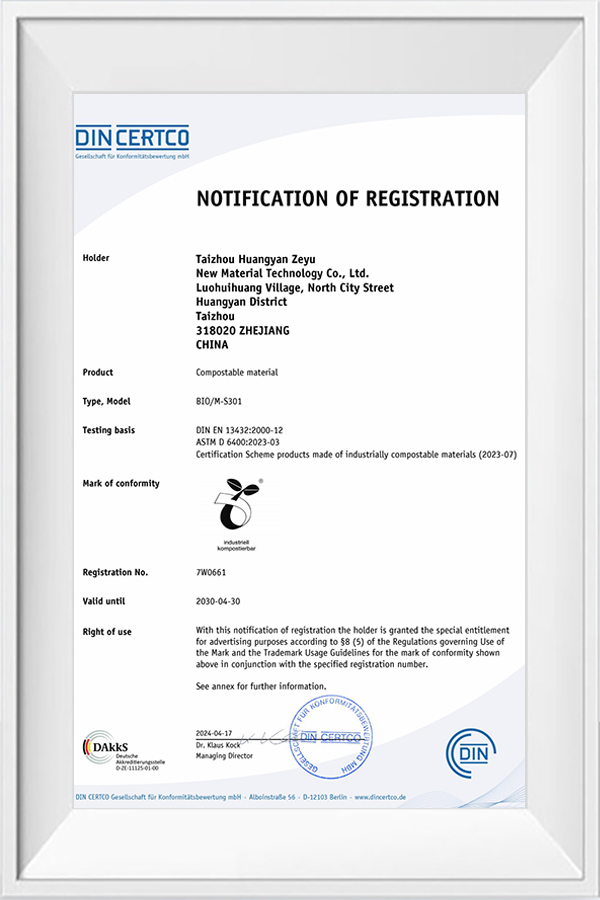

Global vision and green responsibility: The products have passed ISO quality system certification and multiple international environmental standards tests, and are exported to Europe and other regions with strict environmental regulations. Taizhou Huangyan Zeyu New Material Technology Co., Ltd. actively responds to the global circular economy concept and helps customers build a greener and more competitive supply chain.