Performance characteristics of fully biodegradable cast film

Fully biodegradable cast film is an environmentally friendly film material made of polybutylene adipate/terephthalate, polylactic acid, bio-based starch, etc. as the main raw materials, and prepared by cast extrusion process. Compared with traditional petrochemical-based plastic films, cast film has good transparency, flexibility and uniformity, its surface is flat and smooth, and its thickness distribution is consistent. It is widely used in food packaging, daily necessities packaging, electronic product protective film, agricultural covering film and other fields.

Fully biodegradable cast film has excellent longitudinal and transverse tensile properties. Even in a small thickness range, it can maintain good toughness and tear resistance. It is suitable for packaging processes that require stretching, winding and wrapping. Compared with traditional polyethylene film, its tensile breaking strength is equivalent, which meets the needs of automatic packaging machinery operation.

Fully biodegradable cast film shows good heat sealing response speed and edge sealing firmness in the range of 100~130°C, and is suitable for conventional heat sealing packaging equipment without additional modification. Its heat sealing stability enables it to maintain a neat and beautiful sealing effect on high-speed packaging lines, effectively preventing product leakage or moisture.

The material has good cast film forming performance and can be prepared in single or multi-layer composites according to customer needs, such as dry composite or co-extrusion composite with starch-based film, PLA film, paper, etc., to form a multifunctional packaging structure with oxygen barrier and moisture-proof properties. At the same time, the film has suitable surface tension and is easy to print pictures and texts, which is conducive to brand communication.

Because the cast film process gives the film an excellent smooth surface, its transparency and glossiness are significantly better than those of blown film, which can clearly display the contents of the package and enhance the shelf appeal. It is especially suitable for food and daily chemical packaging with high requirements for appearance display.

In terms of environmental protection properties, fully biodegradable cast film can be degraded by microorganisms in natural environment or industrial composting conditions, and finally generate carbon dioxide, water and biomass, achieving complete harmless treatment, avoiding environmental problems such as the difficulty of traditional plastics to degrade and the formation of microplastic pollution, which is in line with the current national and global policy direction of promoting green, low-carbon and circular development.

In addition to packaging, fully biodegradable cast film also has a broad application space in the agricultural field. It can be used as agricultural covering film for moisture retention, heat preservation, weed prevention, etc. It has similar agronomic effects as traditional mulch films, and can be naturally degraded after use, solving the problem of "white pollution" being difficult to recycle and treat. Especially under the development trend of ecological agriculture, organic agriculture and green agriculture, this type of product has great promotion potential.

Wide application adaptability: meeting diversified packaging needs

Based on its unique performance combination, the fully biodegradable cast film can be flexibly applied to packaging purposes in multiple industries, especially in the context of increasingly stringent environmental regulations and consumers' increasing attention to green packaging. Its application scenarios are expanding:

1. Supermarket fresh and quick-frozen food packaging

It can be used as a pallet cover film or heat shrink packaging film for fruits, vegetables, meat, seafood and other commodities, which not only protects food from pollution and water loss, but also has a good preservation effect. Its degradable characteristics also conform to the environmental protection trend of retailers to promote "plastic reduction packaging".

2. Cold chain transportation and composite frozen bag inner film

The cast film has good low temperature resistance and is suitable for use in refrigerated and frozen environments. When used in combination, it can be used as the inner structure of multi-layer frozen packaging bags to improve the overall sealing and environmental protection properties.

3. Daily chemical products and non-food consumer product packaging

It is suitable for laundry detergent refill bags, facial mask outer packaging, disposable personal care product packaging and other scenarios, taking into account functionality and environmental protection, while showing brand responsibility, in line with the "low-carbon life" consumption concept.

4. Medical and industrial auxiliary packaging

For temporary packaging and inner packaging of some medical consumables and sterile instruments, as well as environmentally friendly turnover packaging of some light industrial parts, fully biodegradable cast film can also provide reliable protection and does not constitute an environmental burden after use.

Zeyu Technology's technical layout and market strength in the field of fully biodegradable cast film

Taizhou Huangyan Zeyu New Material Technology Co., Ltd., as China's leading fully biodegradable material manufacturer, focuses on the research and development, manufacturing and application promotion of green materials, and is committed to promoting the transformation and upgrading of plastic products towards environmental protection and high performance. In the field of fully biodegradable cast film, the company has built a uniquely competitive technology platform and product system with a complete R&D system, advanced production equipment and strict quality control.

Based on biodegradable raw materials such as PBAT, PLA, and starch, Zeyu Technology conducts in-depth research on key indicators such as the physical properties, heat sealing properties, and processing adaptability of cast film. Through precise formula design and multiphase modification technology, it effectively solves the problems of high brittleness, poor heat sealing, and low tensile strength of traditional biodegradable films, and has formed a variety of mature commercial cast film products, which widely serve the domestic and foreign green packaging markets.

The company has its own R&D laboratory and pilot base, equipped with multiple cast film production lines, supporting full-process automated operations from raw material mixing, extrusion, film forming to slitting, with an annual production capacity of more than 10,000 tons. Zeyu Technology also actively carries out integrated "industry-university-research-application" cooperation, and jointly develops projects with many colleges and universities and scientific research institutions to keep product technology continuously updated and enhance the core competitiveness of the enterprise.

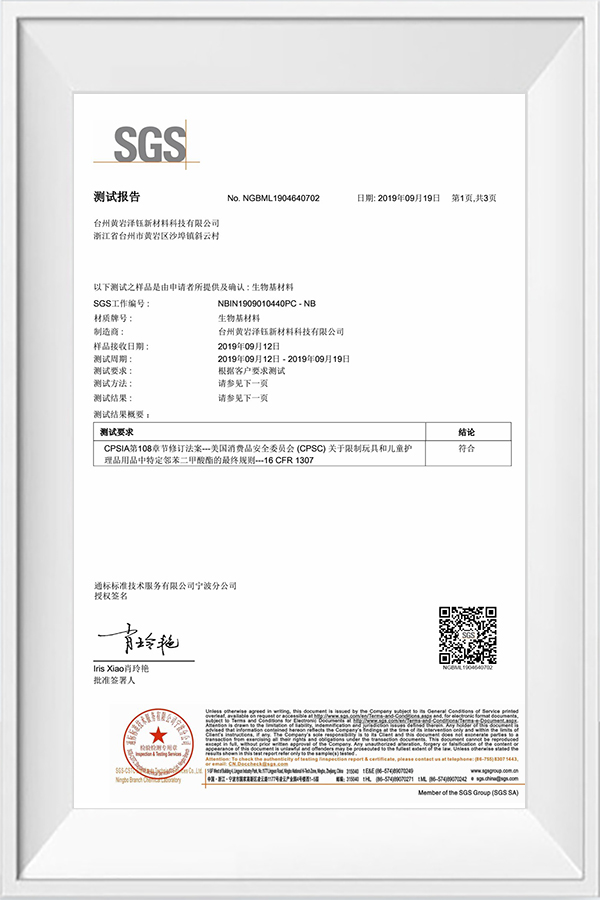

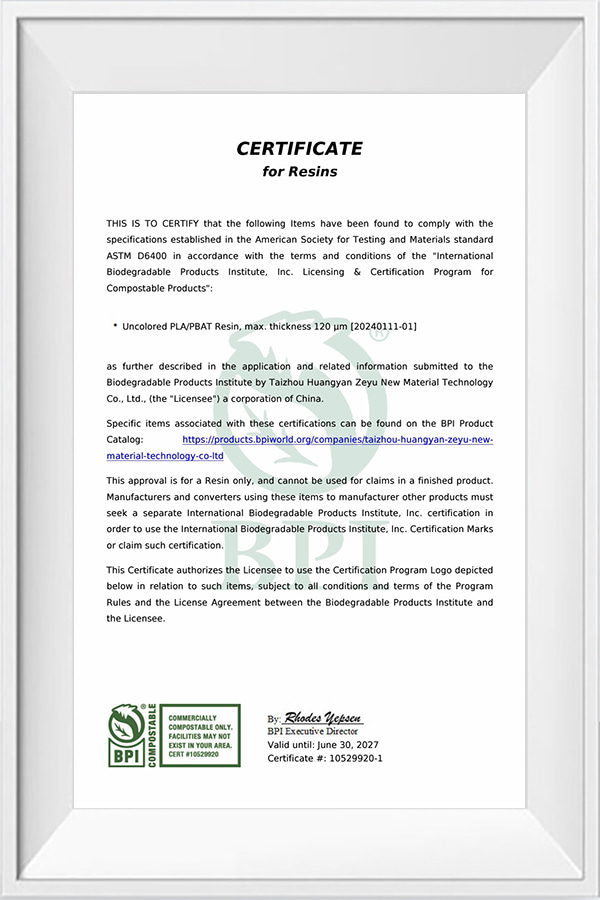

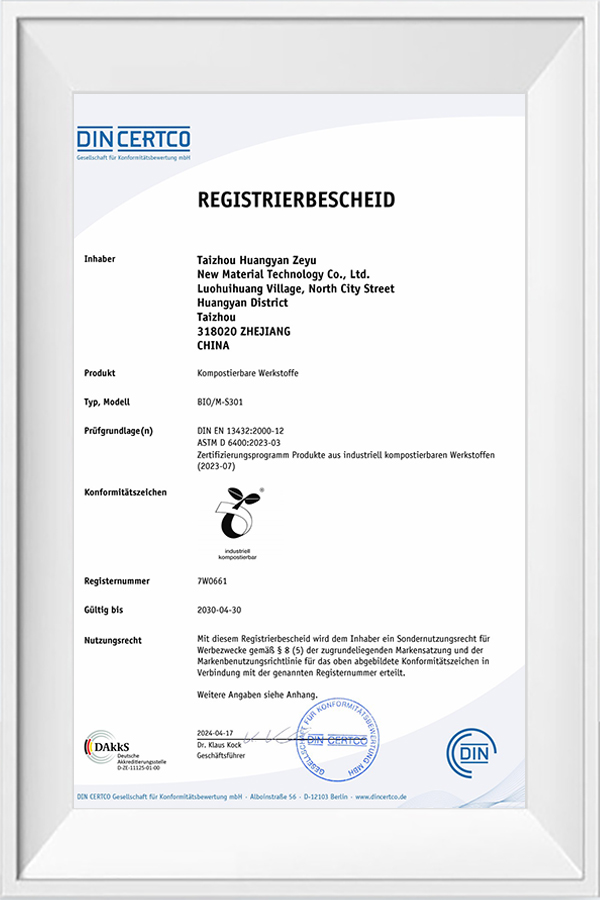

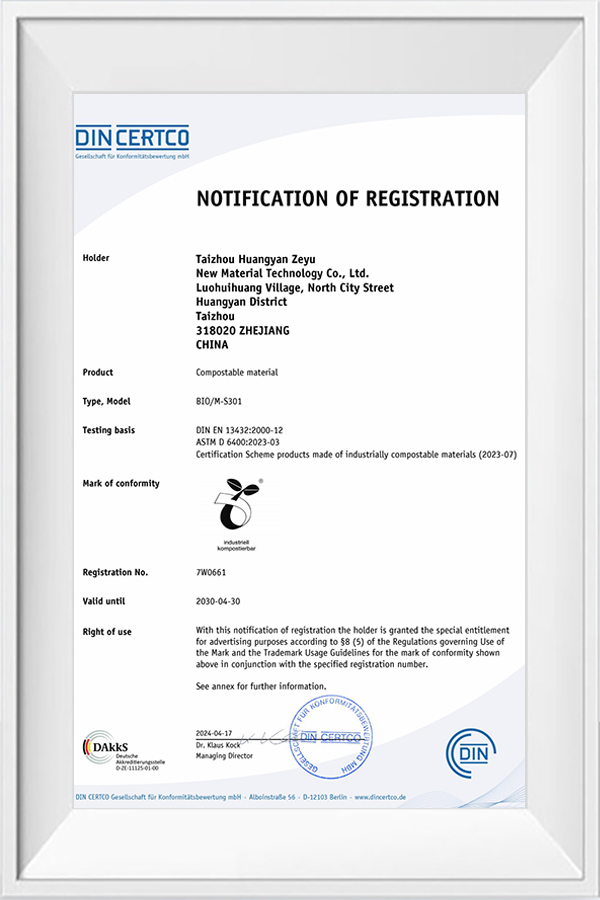

In terms of quality management, Zeyu Technology strictly follows the requirements of GB/T19001-2016 and ISO9001:2015 quality management systems. All products have passed strict mechanical properties, biodegradability and safety tests to ensure that the products achieve a balance between environmental performance and performance and meet diversified market needs.

At present, the company's products are not only sold well throughout the country, but also exported to Europe, America, Southeast Asia, the Middle East and other countries and regions, and are deeply recognized and trusted by customers. Zeyu Technology continues to deepen its development in the field of fully biodegradable cast film through the development concept of "technology-driven product upgrades and environmental protection leading market trends", and is committed to becoming a global leading supplier of green packaging materials.