Reducing plastic from the source: analyzing the core characteristics of fully biodegradable industrial packaging film

Fully biodegradable industrial packaging film is mainly made of PBAT, PLA, starch-based polymers and other basic raw materials, and are prepared through modified blending, extrusion film forming and other processes. This type of film material achieves a balance between flexibility and strength in performance, and is particularly suitable for the "stretching resistance, puncture resistance, and friction resistance" characteristics required for industrial product packaging. Biodegradable films can also achieve good water vapor barrier, UV resistance, and high transparency through compounding or formula adjustment, further improving the "protective" and "display" properties of packaging. This combination of properties makes it widely used in the outer packaging protection of various industrial products such as electronic components, precision machinery, hardware tools, and chemical preparations, ensuring the stability and safety of items during storage and transportation. The most significant advantage of fully biodegradable industrial packaging film is their degradability - under suitable environmental conditions, such as soil, moisture, and natural environments rich in microorganisms, the materials will be enzymatically hydrolyzed by microorganisms, and ultimately no toxic residues will be left, and no "microplastic" risks will be formed.

According to different material proportions and film thickness, this type of film material can usually achieve basic degradation within 3 to 6 months. In practical industrial applications, it is particularly suitable for those one-time application scenarios where "packaging is discarded". Compared with traditional petroleum-based plastic films such as PE and PP, which must be incinerated or landfilled, have high recycling costs and high pollution risks, biodegradable films avoid the hidden dangers of "difficult to handle" and "great harm" from the source, and truly return to nature after use, realizing a closed loop of resources.

Performance advantages of fully biodegradable industrial packaging film

1. Strong environmental friendliness and thorough degradation

fully biodegradable industrial packaging film does not require industrial composting conditions in the natural environment, and can be decomposed into water and carbon dioxide by soil microorganisms within 3 to 6 months. There is no harmful residue in the degradation process, and no microplastic particles are produced, truly achieving "zero pollution" to the environment. It is especially suitable for manufacturing companies and export-oriented companies that focus on sustainable development.

2. Possessing excellent packaging protection properties

This type of film material is comparable to traditional plastic films in terms of transparency, tensile strength, heat sealing performance, moisture and dust resistance, and even performs better in flexibility and tear resistance. It can effectively protect the integrity and cleanliness of industrial products such as electronic components, mechanical parts, and chemicals during transportation and storage.

3. Strong adaptability to meet the processing needs of multiple scenarios

The material can adapt to a variety of processing technologies such as film blowing, casting, lamination, printing, etc., and is suitable for manual or automatic packaging production lines. The film thickness, width, and surface treatment method can be customized according to customer needs to adapt to the packaging standards of different industrial products.

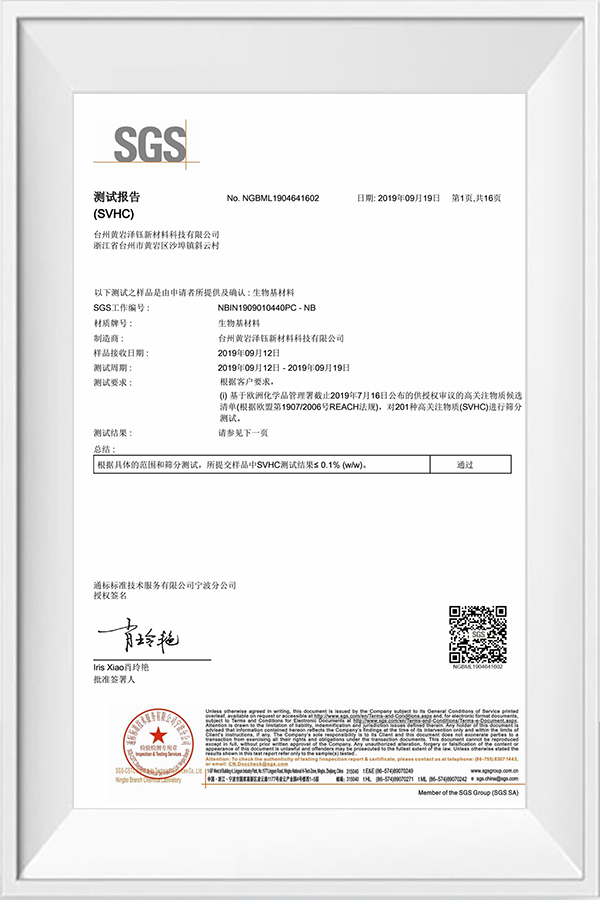

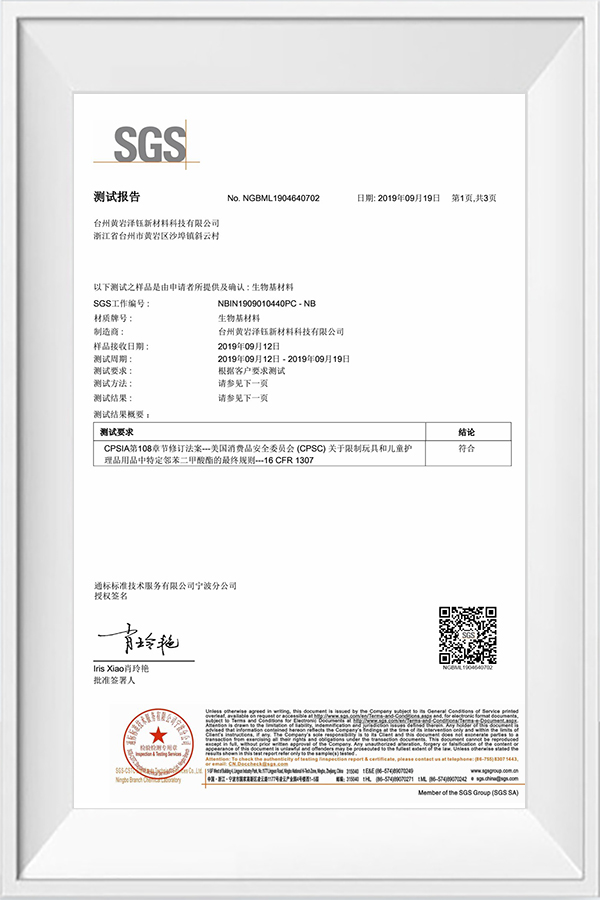

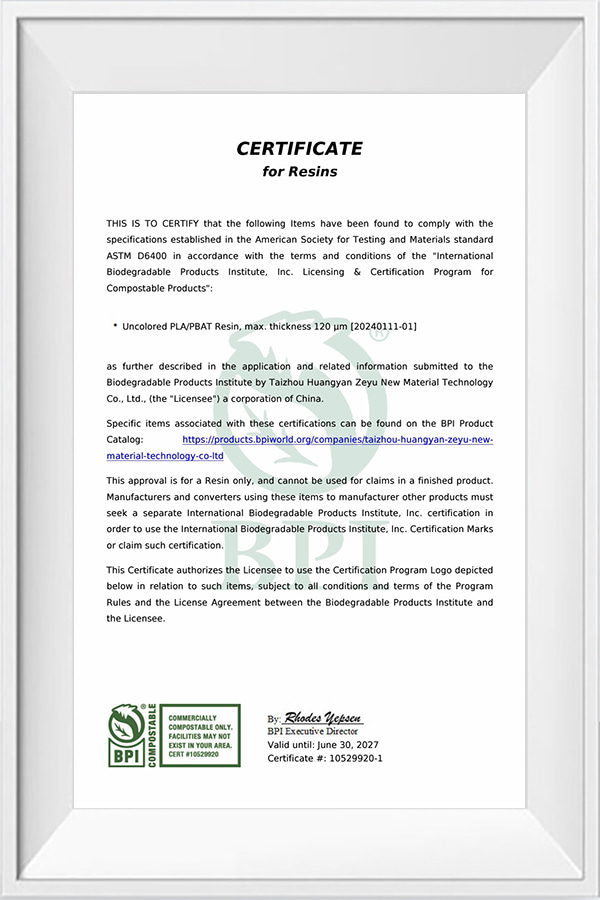

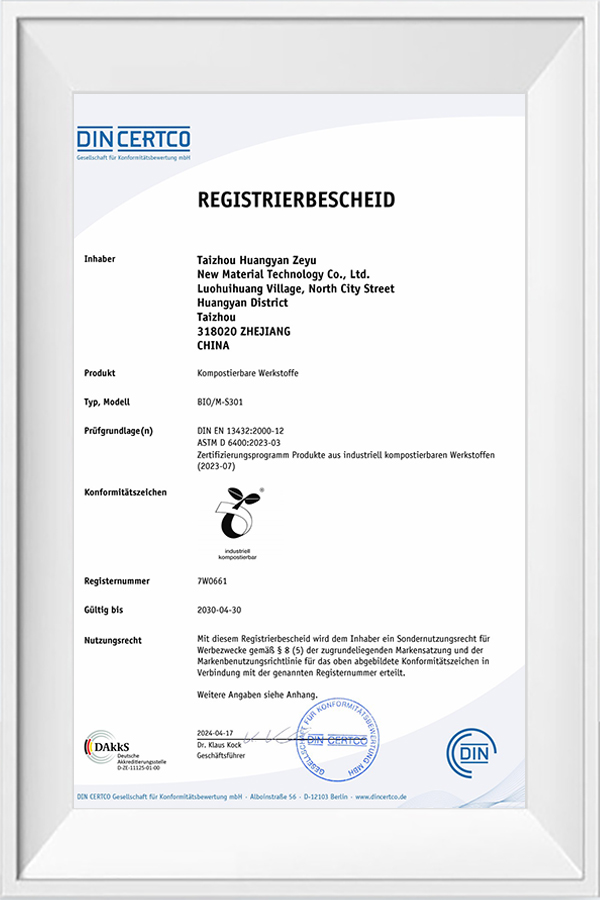

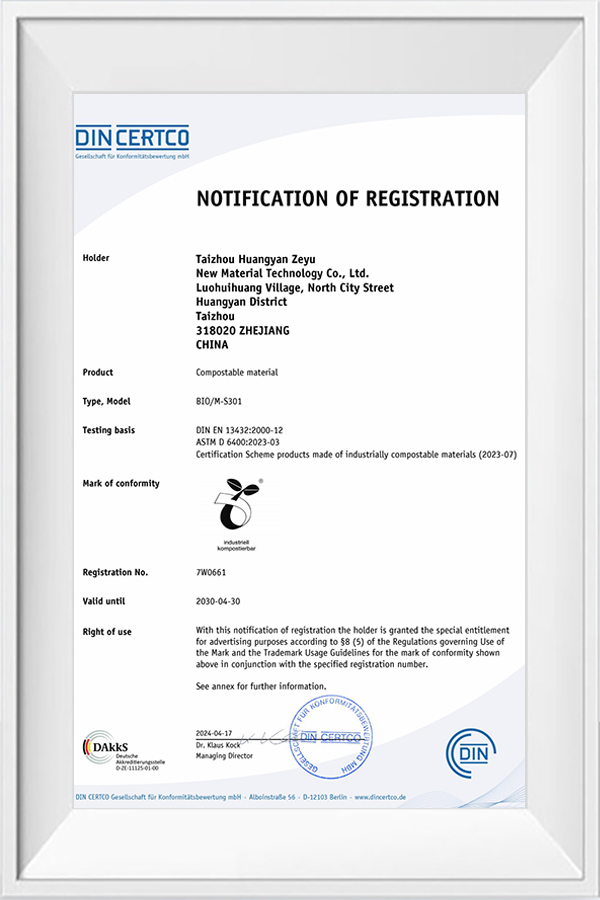

4. Safe and non-toxic, in line with food and industrial grade certification

The source of raw materials is clear, does not contain harmful ingredients such as plasticizers and heavy metals, and complies with many international environmental protection standards such as European and American ROHS, REACH and EN13432. It is especially suitable for industrial products that need to be exported, which helps companies improve product added value and international competitiveness.

5. Help companies shape a green brand image

At a time when brand ecological responsibility is increasingly valued, the use of fully biodegradable packaging film can significantly enhance the company's environmental image in the minds of customers and the public, in line with green procurement policies and customer ESG supply chain audit standards.

Wide application fields, expanding the boundaries of green packaging

Fully biodegradable industrial packaging film is widely used in electronics, electrical appliances, instruments and meters, mechanical parts, precision molds, hardware tools, industrial supplies and chemical materials due to its excellent performance and environmental protection characteristics, including the following typical scenarios:

Electronic product packaging: Electronic components (such as chips and PCB boards) that are sensitive to static electricity and have high requirements for cleanliness are packaged with fully degradable films, which are not only dust-proof and moisture-proof, but also avoid the static electricity accumulation problems caused by traditional plastics.

Packaging of mechanical accessories and metal parts: To prevent oxidation, corrosion and transportation damage, the packaging film must have high strength and sealing. While ensuring performance, the degradable film solves the problem of difficult cleaning of plastic residues and improves the environmental protection level of warehousing and factories.

Packaging of chemical raw materials and fine materials: It is particularly suitable for long-term transportation and warehousing needs. The material itself is resistant to certain chemical corrosion, and the moisture and oxygen barrier functional layer can be customized according to the characteristics of the material to improve the overall packaging protection level.

Export product packaging: It meets the green environmental protection regulations of developed countries such as Europe and the United States, avoids customs clearance difficulties or returns due to non-compliant packaging, and is a "green pass" for the export of industrial products.

Enterprise Strength Guarantee: Taizhou Huangyan Zeyu New Material Technology Co., Ltd.

As a leading domestic manufacturer of biodegradable plastic materials, Taizhou Huangyan Zeyu New Material Technology Co., Ltd. has formed a complete R&D, production and sales system in the field of fully biodegradable industrial packaging film with years of technical accumulation and market experience. The company has an independent technology research and development platform, dedicated to the functional modification and compounding research of raw materials such as PBAT and PLA, and has developed a number of core formulas with independent intellectual property rights.

The company has passed the GB/T19001-2016 and ISO9001:2015 quality management system certification, which means that it has formed a standardized, scientific and traceable management mechanism in all aspects such as product design, raw material procurement, production process control, quality inspection, and after-sales service. This not only ensures the stability of the performance of each batch of products, but also enhances the company's adaptability when facing different market access requirements (such as environmental protection regulations such as the European Union and the United States). In actual implementation, the company is equipped with a strict quality control team and advanced testing equipment to monitor the core parameters of the product, such as biodegradation rate, physical strength, thermal stability, thickness uniformity, and environmental protection indicators, throughout the entire process to ensure that every roll of film, every straw, and every piece of packaging product delivered meets the predetermined standards.