What is fully biodegradable film bag material?

Fully biodegradable film bag material is a new type of green and environmentally friendly polymer material based on natural renewable resources and made through scientific proportioning, polymerization and modification processing. It achieves a good balance between performance and environmental friendliness, and is particularly suitable for sustainable packaging alternatives in the context of the current plastic pollution crisis.

1. Complete degradation path:

Unlike "compostable" or "partially degradable" materials, fully biodegradable film bag materials can be completely decomposed into carbon dioxide, water and a small amount of biomass under the action of microorganisms in the natural environment, and fully integrated into the ecological cycle system:

Under composting conditions, more than 90% of the degradation can be completed within 180 days;

In natural environments such as soil, fresh water, and oceans, it can also achieve no residue degradation within 6-12 months

2. Performance and environmental adaptability:

Compared with traditional PE and PP plastics, fully biodegradable film bag materials have the following core application characteristics:

Good flexibility and friendly feel, suitable for film applications;

Strong heat sealing performance, suitable for high-frequency packaging line operations;

Can be stored at low temperature and hot pressed at high temperature to meet the needs of multiple scenarios such as refrigeration and heat sealing;

Easy to dye and print, with clear and vivid patterns.

Technical advantages of fully biodegradable film bag materials

1. Strong biodegradability: In aerobic composting, soil, and moist natural environments, fully biodegradable film bag material can be completely decomposed into water and carbon dioxide by microorganisms within 3-6 months, without forming microplastics and causing no pollution to soil and water bodies.

2. Good mechanical properties: By rationally regulating the ratio of PBAT to PLA, starch and other ingredients, the material can be optimized in terms of tensile strength, puncture resistance, heat sealing performance, etc., ensuring the stability of the bag body in load-bearing and daily use.

3. Soft and easy to process: The material has good flexibility, soft feel, strong resilience, good anti-breakage ability, and is not prone to brittle cracking or hardening. It is suitable for film bag production processes such as film blowing, calendering, and extrusion, and is easy to mass-produce and industrialize.

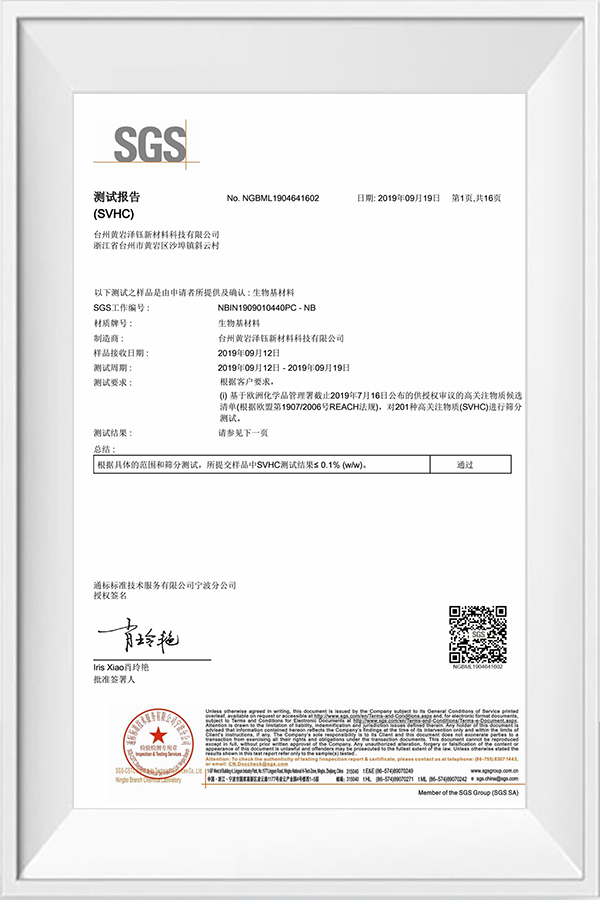

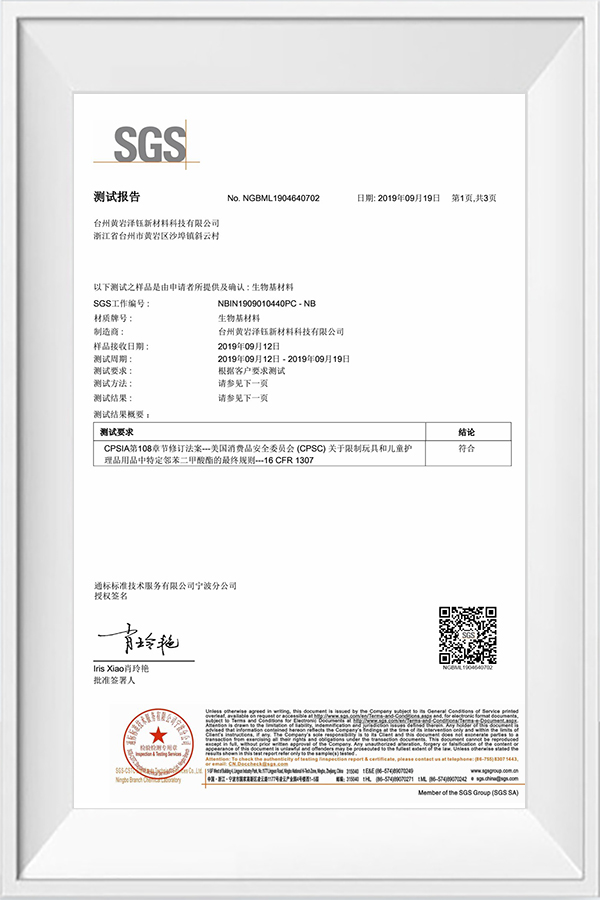

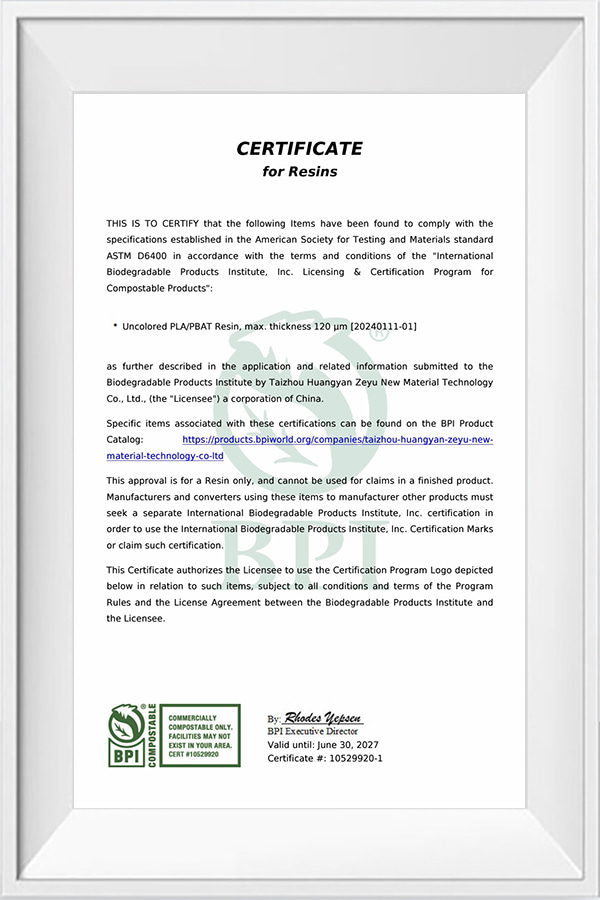

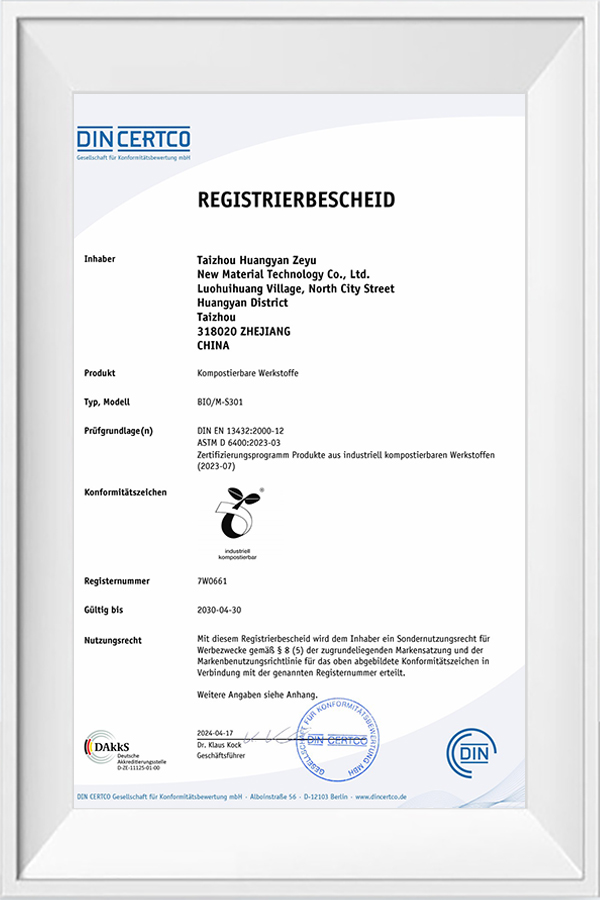

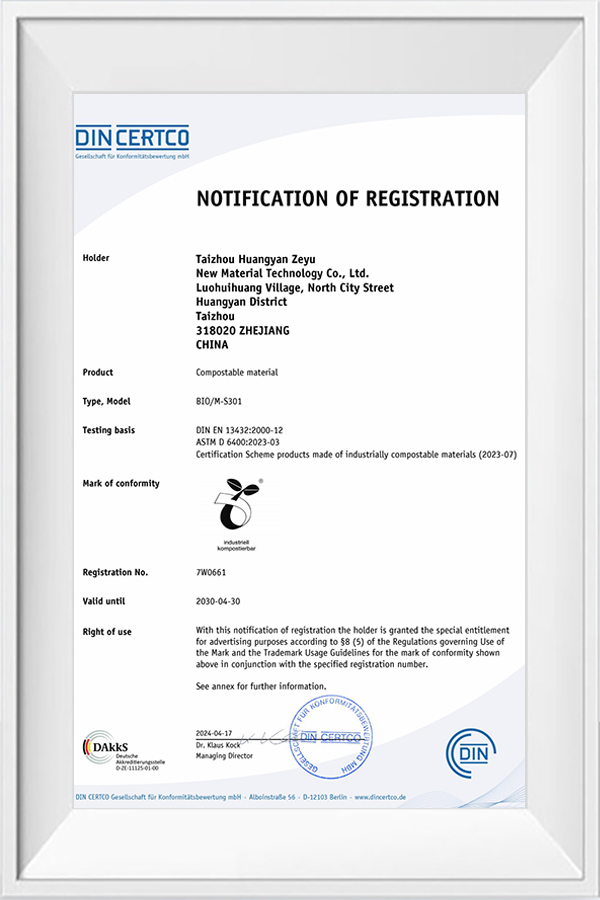

4. Safe and non-toxic: It does not contain harmful ingredients such as heavy metals, phthalates, and bisphenol A, and complies with biodegradable material standards and food contact safety standards such as EU EN13432, US ASTM D6400, and China GB/T 38082. 5. Strong plasticity: Functional additives can be added according to the use requirements to achieve extended performance such as anti-fog, waterproof, and anti-oxidation, meeting the customized needs of different usage scenarios.

Typical application scenarios

Fully biodegradable film bag materials based on environmentally friendly raw materials such as PBAT, PLA and modified starch not only have good mechanical strength, flexibility and processing adaptability, but also because of their completely degradable, non-toxic and harmless ecological properties, they are widely used in multiple daily and industrial fields, promoting the upgrading of plastic products to environmentally friendly substitution.

1. Degradable shopping bags: Fully biodegradable handbags are very similar to traditional PE bags in appearance, load-bearing, flexibility, etc., and support color printing, heat sealing, punching and other processes. Not only can they meet the daily use needs of supermarkets and convenience stores, but they can also print corporate LOGO or environmental protection slogans to enhance the green image of the brand; they are durable, not easy to break, and suitable for repeated use; after use, they can be directly put into wet garbage or composting systems for treatment, which meets the urban garbage classification standards.

2. Environmentally friendly garbage bags: In scenarios such as domestic garbage, medical garbage, gardening garbage, and industrial waste, fully biodegradable garbage bags have excellent stretchability and heat sealing properties, can carry a certain weight, and adapt to the transportation process; strong sealing performance, effectively isolate odor and liquid leakage; can be composted and degraded with organic matter in the garbage disposal process to avoid secondary pollution caused by incineration or landfill.

3. Food packaging bags: Thanks to the food contact safety characteristics of PLA and the flexible support of PBAT, fully biodegradable film bags are widely used in short-term packaging of fresh fruits and vegetables, meat, cooked food, bread, etc.; refrigerated and frozen food packaging bags, lunch bags, etc., have good low temperature resistance; the material does not contain bisphenol A and phthalate additives to ensure that the original flavor of the food is not polluted.

4. Agricultural mulch and seedling bags: In the agricultural field, the traditional PE mulch has a serious problem of residual, which affects the soil structure and crop growth. The fully biodegradable film bag material can be directly applied to agricultural covering film. It does not need to be recycled after use. It can be directly plowed into the soil and degraded into water and carbon dioxide by microorganisms; the seedling nutrient bags and nutrient pots can penetrate with the root system during the planting process, and finally enter the soil environment with the plants to decompose together; the material can adjust the degradation cycle to match the planting cycle of different crops and improve the farming efficiency.

Enterprise advantages: Create professional strength in fully biodegradable film bag materials

As a leading domestic fully biodegradable plastic solution provider, Taizhou Huangyan Zeyu New Material Technology Co., Ltd. has many outstanding advantages in the research and development and production of fully biodegradable film bag materials with its technical accumulation, R&D capabilities and industrial supporting facilities:

1. Perfect R&D system, innovation-driven green material upgrade

Relying on its independent R&D platform, the company has mastered the core modification technology of degradable raw materials such as PBAT, PLA, and starch, and can flexibly adjust the formula according to the needs of downstream customers to achieve a balance of performance in terms of degradability, heat sealing, flexibility, and printing adaptability. At the same time, it has established "industry-university-research" cooperation with many domestic universities and research institutes to effectively promote the transformation of scientific research results and the iterative upgrading of material systems.

2. Diversified product matrix to meet multi-scenario packaging applications

Zeyu New Materials has established a product system with fully biodegradable film bag materials as the core, and extended to multiple categories such as disposable tableware, straws, and foam replacement materials. It has the ability to provide systematic green packaging solutions for multiple industries such as retail, supermarkets, logistics, and agriculture.

3. Mature production capacity and quality assurance

The company is equipped with modern production lines, has large-scale stable production capabilities, supports a variety of molding methods such as film blowing, extrusion, and thermoforming, and strictly implements GB/T 19001-2016 and ISO9001:2015 quality management system standards, and controls the selection of raw materials, production process control, and finished product testing at all levels to ensure material performance consistency and food contact safety.