What are fully biodegradable food-grade contact materials?

As the name suggests, fully biodegradable food-grade contact materials are high-molecular environmentally friendly materials that meet food contact safety standards and can be completely decomposed in the natural environment. Not only does it not release harmful substances during food contact, ensuring that it is harmless to the human body, but it can also be decomposed into water and carbon dioxide through microbial degradation in the soil or compost environment after being discarded, and will not cause secondary pollution to the soil, water or atmosphere.

This type of material is mainly made of renewable resources, and several common basic components include:

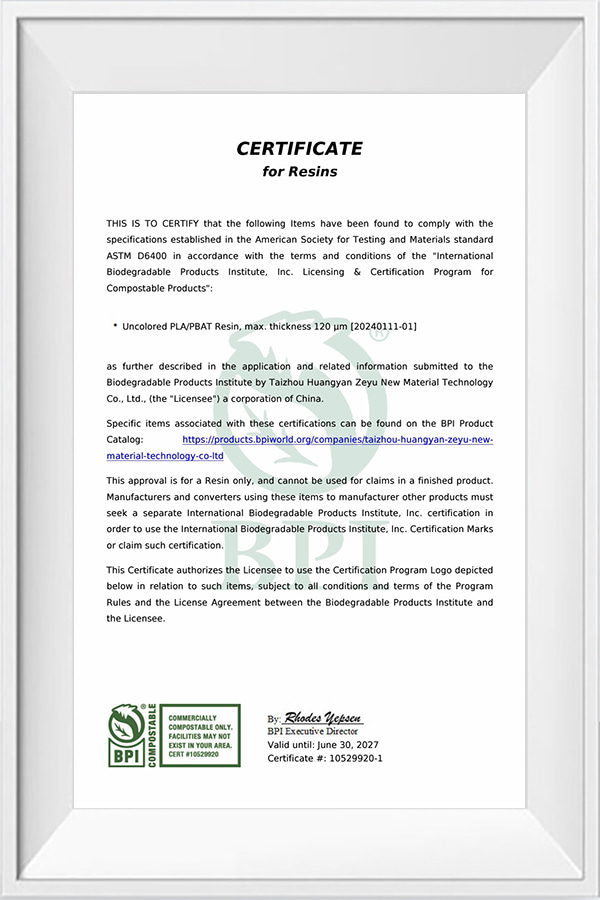

PBAT (polybutylene adipate/terephthalate): an aliphatic-aromatic copolyester with good flexibility and excellent degradability, which is one of the most widely used degradable materials at present;

PLA (polylactic acid): fermented from natural starches such as corn and cassava, with good rigidity and high transparency, it is a typical bio-based degradable plastic;

Modified starch, bio-based polyester: as a filler or modified substrate, it can reduce costs and improve degradation speed and environmental adaptability.

These ingredients are processed by compounding, melting, copolymerization, modification and other processes, so that the finished materials have stable performance during use and can be completely degraded after being discarded.

Performance of fully biodegradable food-grade contact materials

Core performance advantages: dual balance of environmental protection and practicality

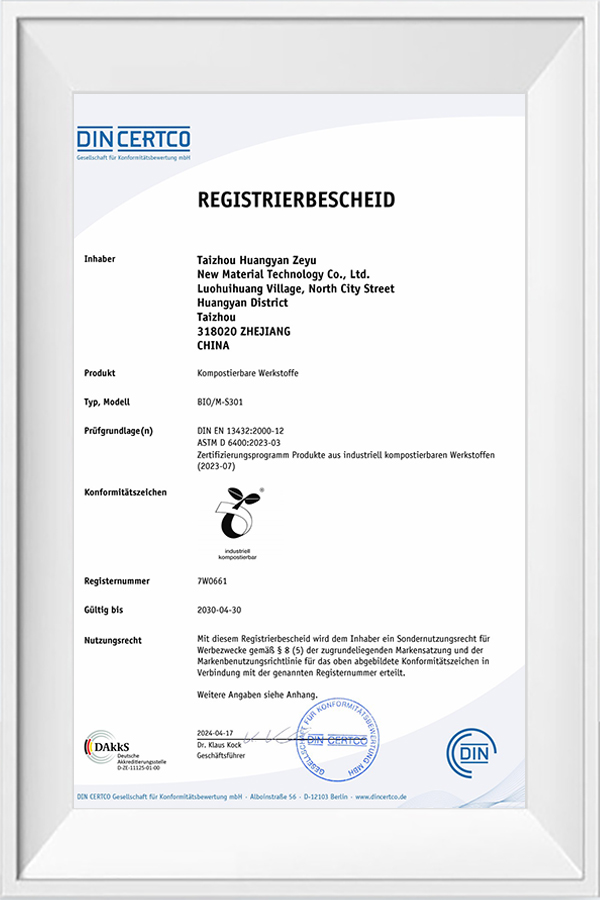

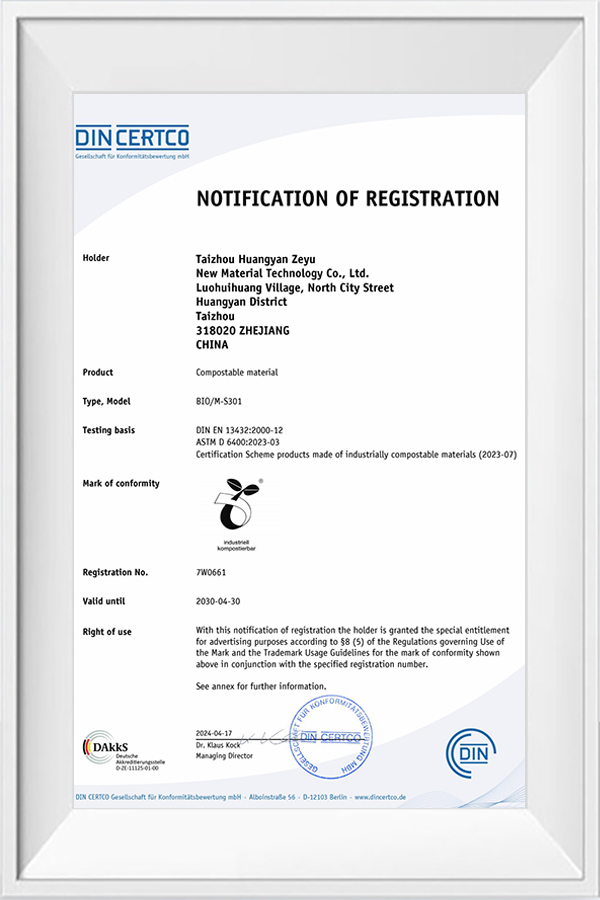

Fully biodegradable: In compost, aerobic soil, and moist natural environment, the material can be completely decomposed by microorganisms within 3-6 months without residue or pollution.

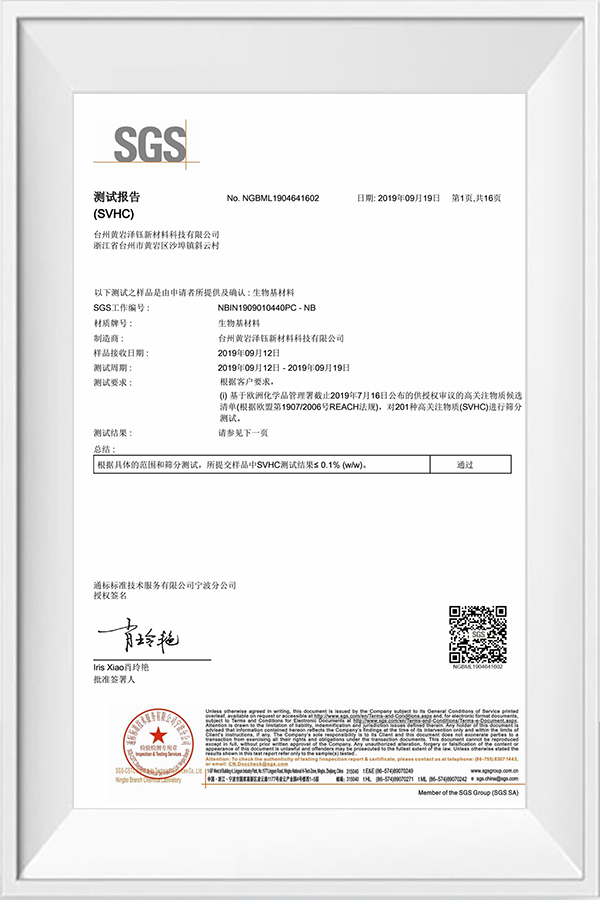

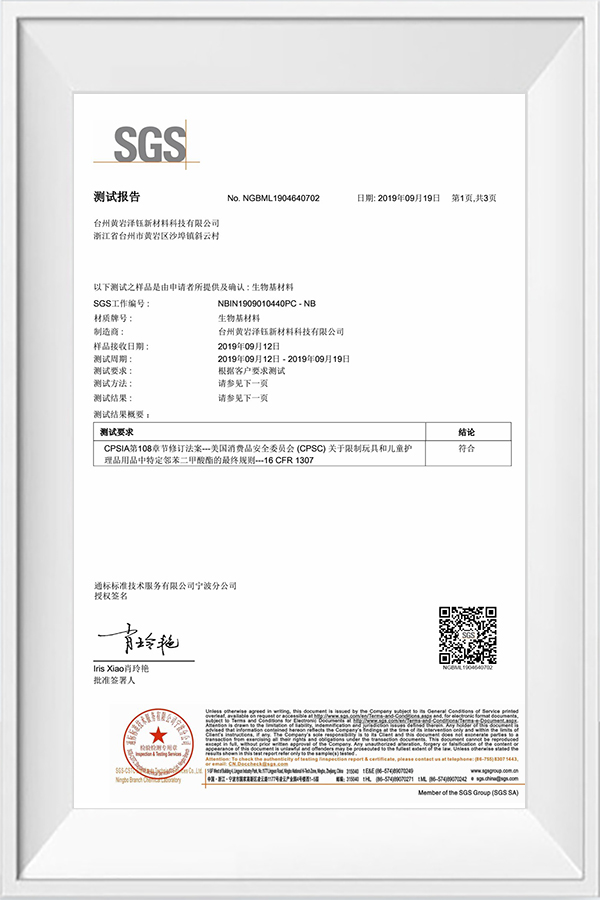

Food grade safety: Meets food contact standards such as China GB 4806 series, US FDA, and EU EU 10/2011, and does not contain heavy metals, phthalates, bisphenol A and other harmful substances.

Taking into account thermal stability and structural strength: Can withstand hot pressing, extrusion, edge sealing and other operations during food processing and packaging; some materials can also be suitable for microwave heating, refrigeration and freezing.

Strong processing adaptability: It can be processed and produced by various methods such as film blowing, injection molding, blister molding, calendering, thermoforming, etc., which is convenient for production on various industrial equipment.

Good visual and tactile feel: The material can present a translucent or milky white appearance, with a smooth and soft touch, and can replace the packaging texture of traditional PE and PP materials.

Typical application scenarios: Green upgrades are accelerating penetration

Disposable degradable tableware: including knives, forks, spoons, beverage cups, food trays, and covered bowls, which are widely used in takeout, supermarkets, and airline catering services;

Food packaging films and bags: such as plastic wrap, zipper bags, and freezer bags, suitable for packaging fruits, cooked food, and quick-frozen foods;

Beverage bottles and milk bottle shells: Made of PLA or PBAT copolymer technology, they meet high transparency and high cleanliness requirements;

Takeaway packaging boxes and straws: As an alternative solution to the ban on plastic straws, they are widely supported by the government and businesses.

Environmental significance: A realistic choice to end "white pollution"

Compared with traditional petrochemical plastics (such as PE, PP, PS, etc.), fully biodegradable food-grade contact materials reduce carbon footprints from the source and achieve true "zero emissions" after use. They do not require industrial landfills, do not cause persistent pollution, and can return to the natural cycle. It has significant positive significance for marine plastic pollution control, urban garbage reduction, agricultural ecological protection and other aspects.

At the same time, the application of this material is also conducive to promoting green consumption concepts, advocating a low-carbon lifestyle, and helping the government achieve the "dual carbon" goal and circular economic development strategy.

Technical background and performance advantages

Taizhou Huangyan Zeyu New Material Technology Co., Ltd. is a leading domestic manufacturer and supplier of fully biodegradable food-grade contact materials. It has deep technical accumulation and system solution capabilities in this field. The company focuses on the development of bioplastic formulas and terminal product innovation based on PBAT, PLA, modified starch, etc., and has formed a relatively complete technology research and development system and mass production capabilities, and has established long-term "industry-university-research" cooperation relationships with many universities and research institutes.

Its independently developed food contact grade materials are particularly outstanding in the following aspects:

1. Strong full biodegradability

Using polybutylene adipate/terephthalate (PBAT) as the core, through material modification, the product can be degraded into harmless water and carbon dioxide in natural environments such as compost, soil or ocean within 3-6 months, without residue or pollution, truly realizing an ecological closed loop from "source" to "destination".

2. Food grade safety guarantee

All products have passed strict food contact safety standard testing and comply with China's GB 4806 series standards and EU EC 1935/2004 and US FDA food contact material regulations. It will not release harmful substances when in contact with food under high temperature, oil, acid and alkali conditions, ensuring food quality and consumer health.

3. Superior mechanical properties and processing properties

Through composite technology and modification treatment, the material has good tensile strength, heat resistance and printability, and can be used for a variety of process routes such as high-speed film blowing, injection molding, blister molding, thermoforming, etc., and is compatible with mainstream processing equipment on the market, making it easy for terminal companies to quickly switch production.

4. Visual and tactile enhancement of consumer experience

This series of materials has a smooth and flexible texture, good transparency and haze control ability, which is especially suitable for high-end food packaging brands pursuing the product positioning of "environmental protection + aesthetics" to enhance the added value of terminal products.

Expansion trend of application scenarios

Fully biodegradable materials are rapidly extending from the traditional packaging field to more scenarios. Taking Zeyu New Materials' products as an example, the main application scenarios include:

Food packaging film: such as plastic wrap, stretch film, and modified atmosphere packaging film, replacing PE plastic film for packaging of fruits, vegetables, meat, and cooked food;

Disposable tableware: including knives, forks, spoons, beverage cups, and packaging boxes, which are widely used in takeout, restaurant chains, and travel airline meals;

Degradable beverage bottles: PLA-based bottles with PBAT bottle caps have been gradually implemented in the beverage and dairy industries;

Composite packaging bags: used for small and medium-sized bagged foods such as snacks, frozen foods, and coffee powder;

Agricultural product packaging: such as fresh vegetables and edible fungi product packaging, to achieve green direct supply from the origin.