What is a fully biodegradable ground film material?

Fully biodegradable ground film material is an eco-friendly film material designed specifically for the agricultural field. It is mainly based on renewable raw materials such as PBAT (polybutylene adipate/terephthalate), PLA (polylactic acid) and modified starch. After special process modification and proportioning, it is made into a film product with both high performance and degradability. Its core features are:

1. It can be completely decomposed into water and carbon dioxide by microorganisms in the natural environment, without residue and pollution: Under the influence of natural conditions such as soil, moisture, temperature and microbial activity, the fully biodegradable mulch film can be gradually decomposed into carbon dioxide, water and a small amount of biomass through biological enzymolysis and microbial metabolism, without producing any toxic and harmful substances, and without forming microplastic residues.

2. It has good strength, weather resistance and coverage in farmland applications to ensure the normal growth of crops: In order to adapt to the requirements of outdoor environment and agricultural machinery operation, the fully biodegradable film has enhanced tensile strength, puncture resistance and toughness through material modification technology, which can withstand the influence of climate such as sun, wind and rain, and ensure the coverage stability of the entire planting cycle. In addition, the film has good ground adhesion and light-shielding properties, which can effectively regulate the surface temperature and humidity, inhibit weeds, prevent water evaporation, provide crops with a better root growth environment, and improve the quality and yield of crops.

3. The degradation cycle is adjustable to meet the agricultural planting needs of different crops and regional climate conditions:

Through the flexible adjustment of the film material formula, a controllable degradation cycle of 3 to 6 months can be achieved, thereby adapting to various short, medium and long-term crop planting needs. For example, different crops such as early-maturing vegetables, spring-sown corn and Chinese herbal medicine, or areas with significant climate differences between the north and the south, can choose the most appropriate mulch film ratio according to the degradation time and agronomic rhythm, so that after completing the agricultural covering function, it can be gradually degraded as needed without affecting subsequent farming, truly achieving the goal of "stable when used, disappearing after use".

Advantage linkage application scenarios: implementation of the dual value of performance and ecology

Fully biodegradable mulch film not only has excellent physical properties and environmental protection characteristics, but also shows obvious benefits in different agricultural scenarios, achieving the perfect fusion of "performance advantages" and "scenario adaptation":

1. Excellent agricultural performance - suitable for grain crop planting

In the planting of field crops such as wheat, corn, and rice, fully biodegradable mulch film can withstand the impact of agricultural machinery rolling and severe climate with its excellent mechanical strength and ductility. At the same time, it has excellent heat preservation and moisture retention effects, effectively increasing ground temperature, maintaining soil moisture, promoting rapid seed germination and root development, and increasing crop yield and quality, providing a guarantee for sustained high agricultural yields.

2. Highly degradable - suitable for vegetable planting bases

In solar greenhouses and greenhouse vegetable planting (such as tomatoes, peppers, cucumbers, etc.), fully biodegradable mulch can be naturally degraded into water and carbon dioxide within 3-6 months after use, without the need for manual recycling, avoiding the damage of residual film accumulation to soil structure and permeability, saving labor costs for film cleaning, reducing hidden dangers of pests and diseases, and at the same time helping to enhance the "pollution-free" image of agricultural products and meet the requirements of green vegetable certification.

3. Strong adaptability and customization capabilities - suitable for cash crops and specialty agriculture

In the refined planting process of high-value-added crops such as tea, grapes, Chinese medicinal materials, and flowers, growers often put forward higher requirements for the degradation cycle, thickness, width and functionality of film materials. Fully biodegradable mulch can be customized according to crop growth cycles and climatic conditions, supporting functional surface treatments such as UV protection, insect prevention, and anti-condensation, better protecting the crop root environment, reducing the risk of agricultural residues, and improving product quality and market competitiveness.

4. Significant environmental ecological value - suitable for ecological farms and green agricultural projects

In ecological agricultural parks, organic farms, modern circular agriculture and other agricultural projects that attach importance to the ecological environment, the use of fully biodegradable mulch can avoid "white pollution", protect the physical and chemical properties of the soil and the microecological balance, and prevent the deposition of microplastic particles; at the same time, its non-toxic, harmless and traceable raw material sources help to improve the overall green certification level of the farm and enhance consumers' trust in the product and brand loyalty.

Driving force: Taizhou Huangyan Zeyu New Material Technology Co., Ltd.

As a leading domestic fully biodegradable plastic manufacturer, Taizhou Huangyan Zeyu New Material Technology Co., Ltd. focuses on the research and development, manufacturing and promotion of green new materials. Based on raw materials such as PBAT, PLA and starch, the company has successfully developed a series of agricultural-specific fully biodegradable products, of which mulch materials are an important component.

1. R&D advantages help balance material performance and degradation

The company has an independent R&D laboratory and material modification platform, which enables the company to:

Precisely control material formula: By scientifically regulating the proportion and structure of PBAT, PLA, starch and other ingredients, it customizes mulch films of different thicknesses, degradation cycles and mechanical strengths to meet the needs of various crops and regional environments.

Overcoming the contradiction of "strength-degradability": It is difficult for traditional mulch films to take into account both agricultural strength and degradability, while Zeyu's R&D capabilities enable the product to have stable physical properties during field use and be efficiently degraded after use, achieving a balance between the two.

Quickly respond to market changes: It can quickly develop new versions of materials or functional films according to climate change, agricultural model upgrades or export standard changes to enhance market competitiveness.

2. Mature product system ensures multi-scenario compatibility and promotion

The company has formed a series of biodegradable products including agricultural mulch films, packaging bags, straws, foam substitutes, etc. The advantages in mulch film applications include:

High efficiency of technology migration: Existing film-forming technology and bag-making processes can be directly reused in mulch film production, reducing development costs and cycles.

Multi-field synergy: Agricultural film can form an ecological chain with other degradable products of the company, meet the green needs of the entire chain such as agricultural planting, packaging and transportation, and increase customer repurchase rate and brand stickiness.

Strong industrial production capacity: With mature experience in batch production and standardization, it can provide stable supply and customization on demand to ensure the film demand for large-scale application projects such as field agriculture and greenhouse planting.

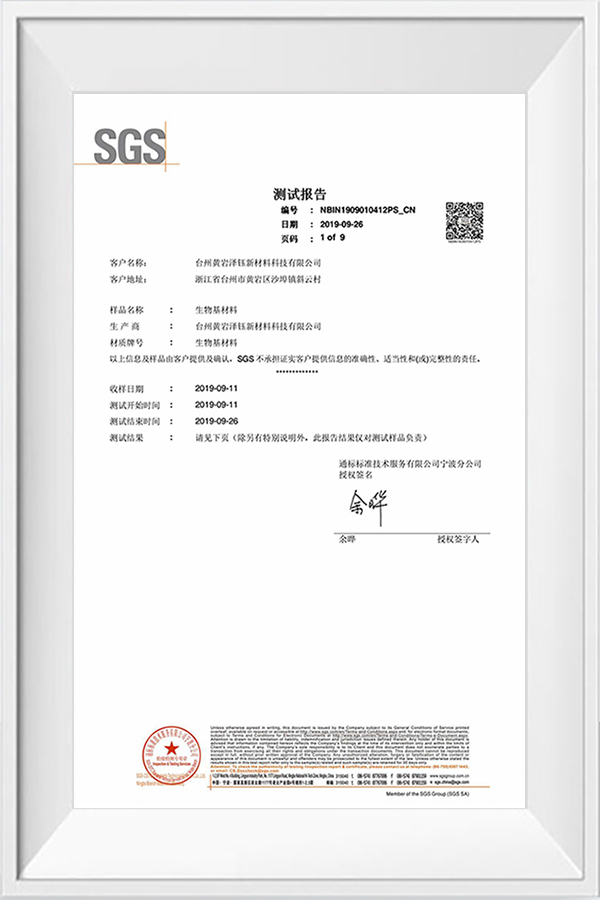

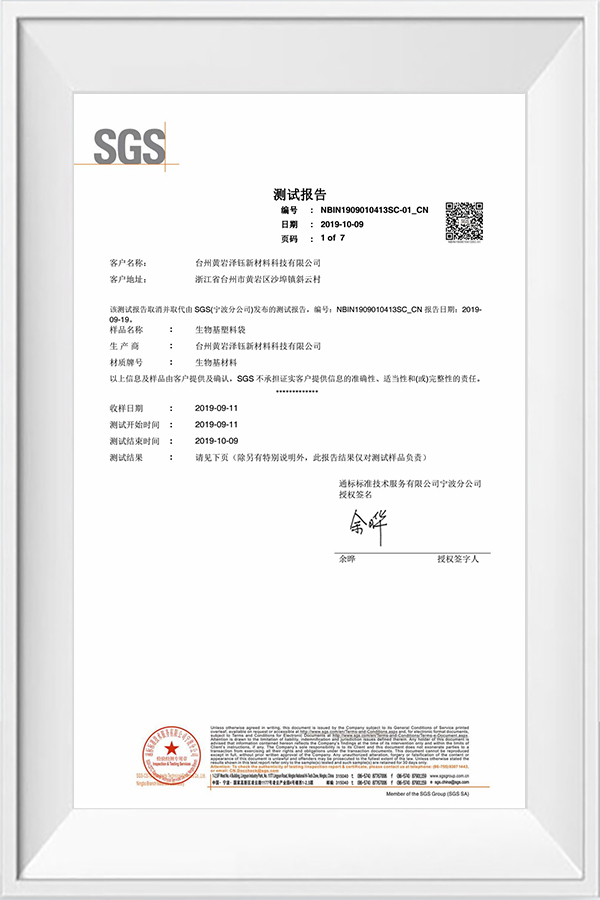

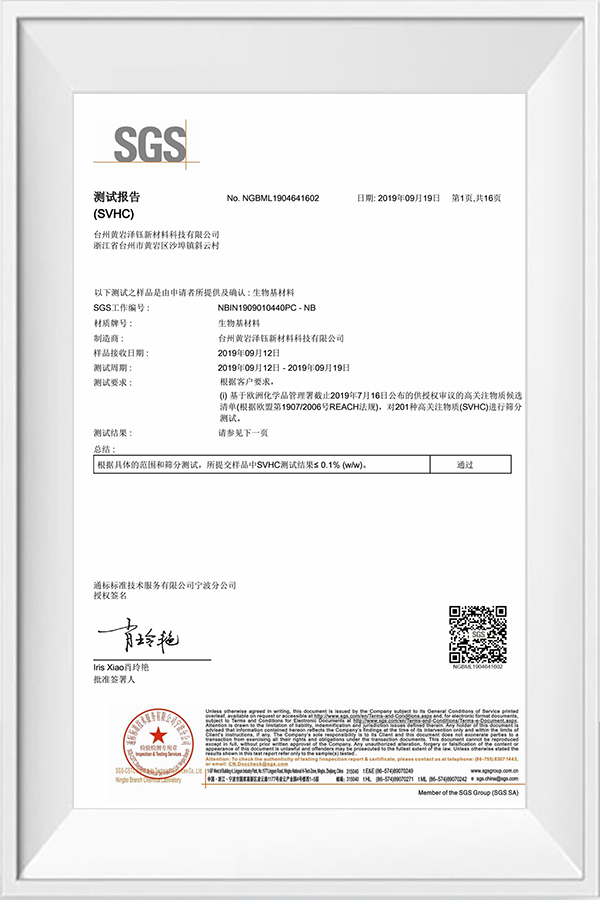

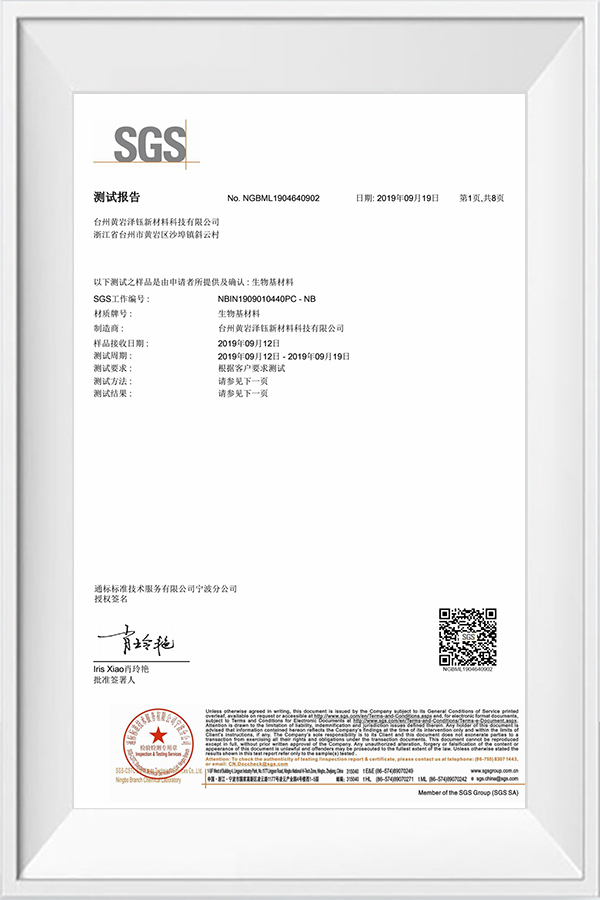

3. Quality system and traceability mechanism enhance trust and export power

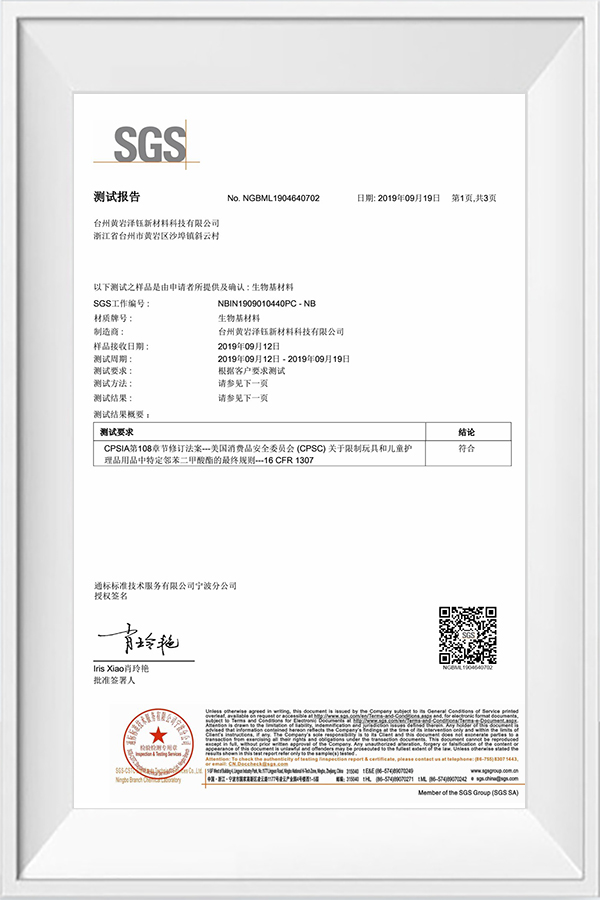

Passing ISO9001 and other quality system certifications, as well as material traceability management, the advantages brought include:

Product quality is more stable and reliable: The purity and performance fluctuations of raw materials are controllable, effectively avoiding incomplete degradation or film breakage and aging during farmland use.

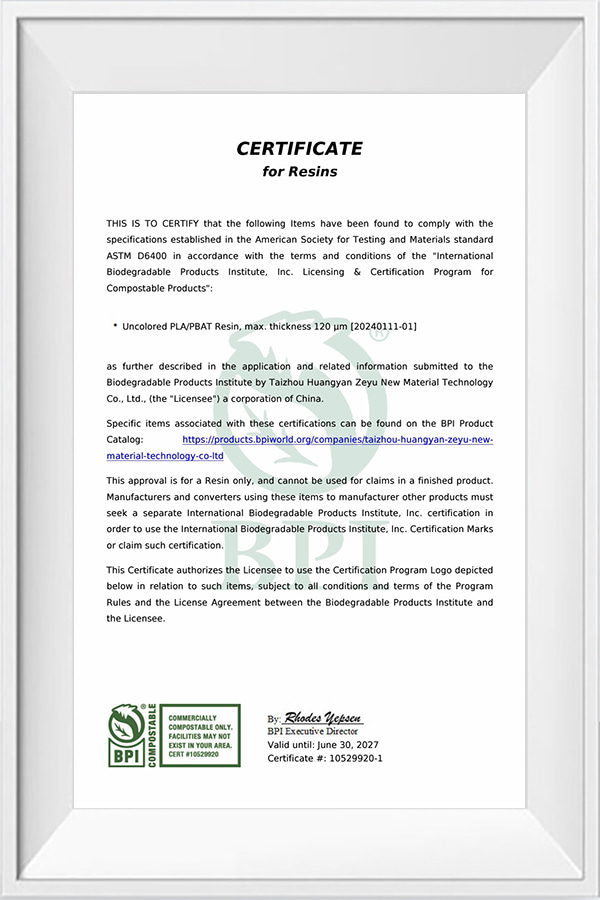

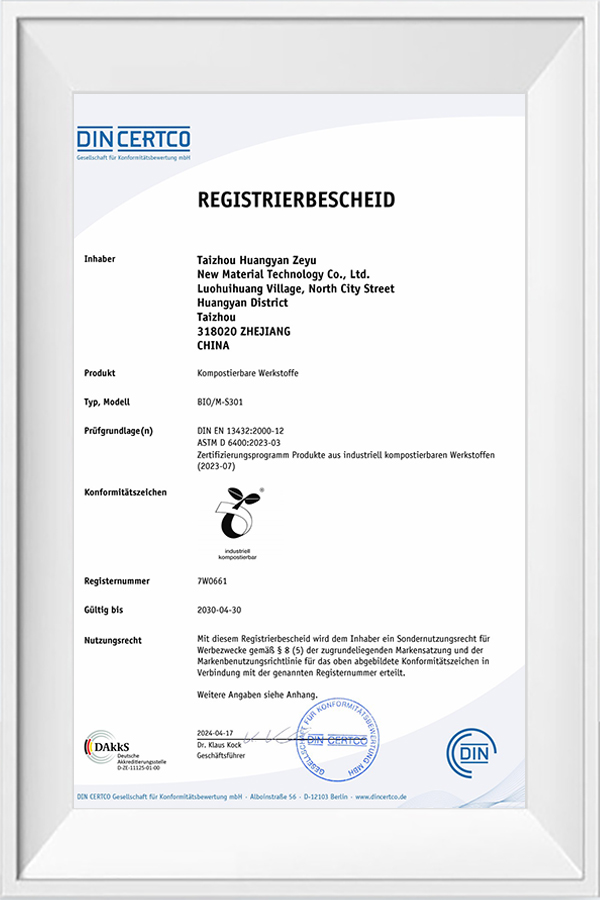

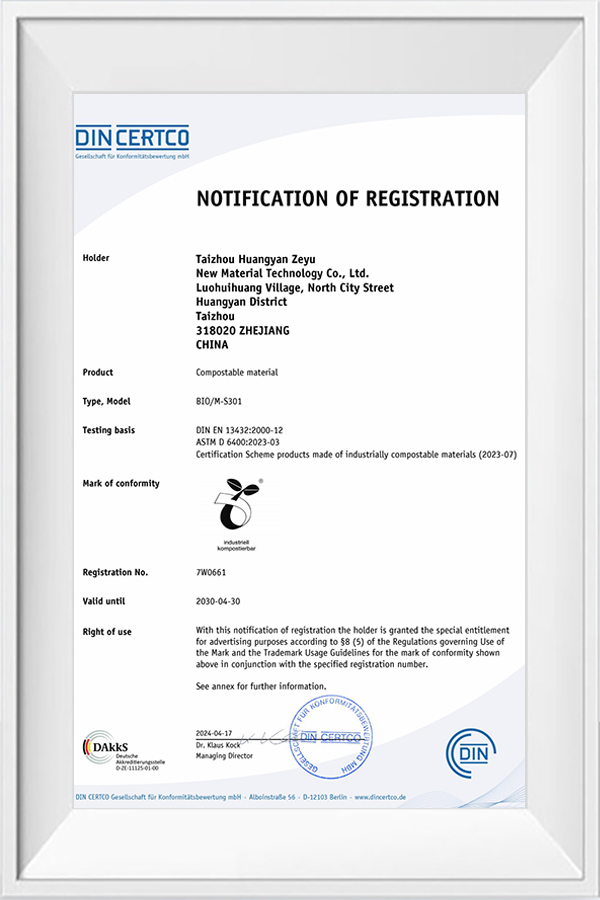

Compliance with regulations and certification standards: Products can pass domestic GB/T 38082, biodegradable film group standard and EU EN13432, US ASTM D6400 and other certifications, providing compliance basis for export or bidding.

Meet the needs of government procurement and brand farms: With the advantage of green certification, it is easier to be included in the procurement list of green agricultural demonstration parks, organic farms, policy subsidy projects, etc.

4. Innovative collaboration drives continuous technological evolution

The industry-university-research collaboration with universities and research institutions not only expands the breadth of the company's technology, but also brings the following benefits:

More forward-looking technology: able to predict new trends in biodegradation and deploy next-generation material technologies such as nano-enhancement and intelligent degradation;

Patent accumulation and intellectual property protection: forming technical barriers, raising market entry barriers, and protecting own research and development results;

Attracting more downstream companies to cooperate: upstream and downstream companies collaborate to develop customized membrane materials, establish an industrial chain cooperation ecosystem, and enhance brand influence.