Overview of fully biodegradable straw materials

Fully biodegradable straw material is a new type of environmentally friendly polymer material made from renewable resources and completely degradable under natural conditions.

Its core components mainly include the following three categories:

Polybutylene adipate/terephthalate: This is a thermoplastic degradable aliphatic-aromatic copolyester that combines the flexibility and biodegradability of plastics and is one of the most commercially promising biodegradable materials.

Polylactic acid: It is polymerized after extracting lactic acid from plant starch such as corn and sugarcane. It has good rigidity, transparency and thermal stability, and is widely available and renewable.

Bio-based materials such as modified starch: After physical or chemical modification of natural starch, its thermoplasticity and processability are improved, which can enhance the molding effect and environmental protection properties of the straw.

Through advanced blending modification technology and process control, these materials can achieve good physical properties, such as bending resistance, pressure resistance, heat resistance and smooth surface texture, and the user experience is almost the same as traditional plastic straws.

This type of straw can be completely decomposed by microorganisms in nature after use, and eventually produces carbon dioxide and water. The whole process will not produce harmful residues or microplastics, and will not cause secondary pollution to soil, water or air. Its degradation cycle is generally 3 to 6 months, depending on factors such as ambient temperature, humidity, and microbial activity. This degradation ability makes it independent of industrial composting facilities and does not require recycling, greatly reducing terminal processing costs and environmental risks.

Fully biodegradable straw materials also have excellent processing adaptability and can be applied to conventional extrusion, injection molding, blow molding and other process flows, adapting to existing straw production equipment, greatly reducing the threshold for enterprise transformation.

Performance advantages drive diversified applications, and the market prospects for fully biodegradable straw materials are broad

Fully biodegradable straw material is becoming the preferred material to replace traditional plastic straws worldwide with their outstanding environmental attributes and excellent comprehensive performance. Its application is extending from the food and beverage industry to public places, education systems and international export markets, promoting the rapid popularization of green consumption patterns.

1. Environmental friendliness: meeting global demands for plastic reduction

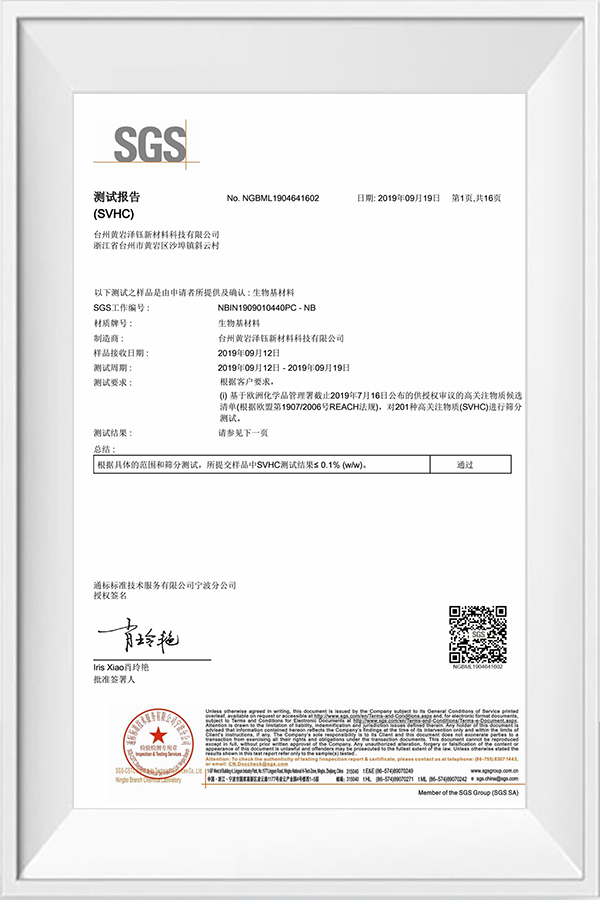

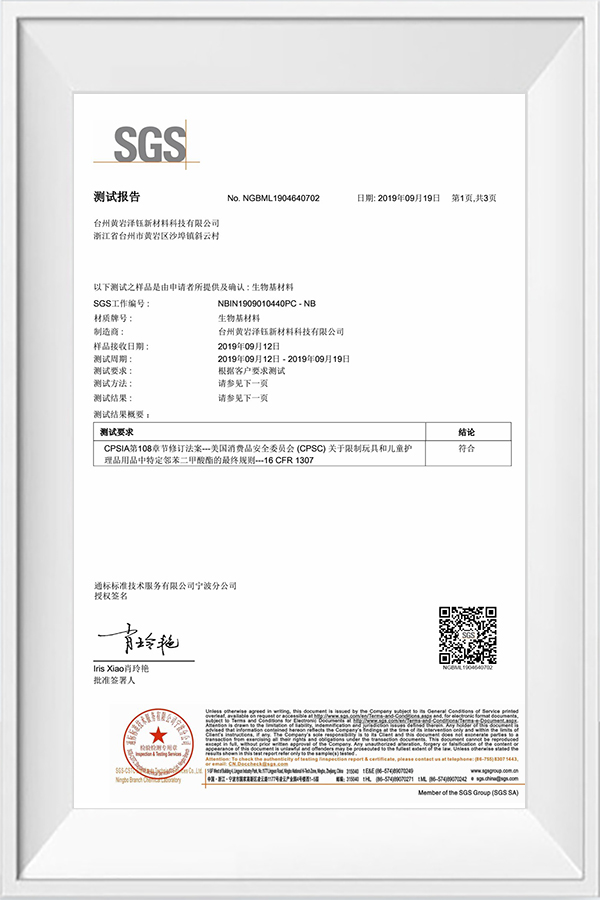

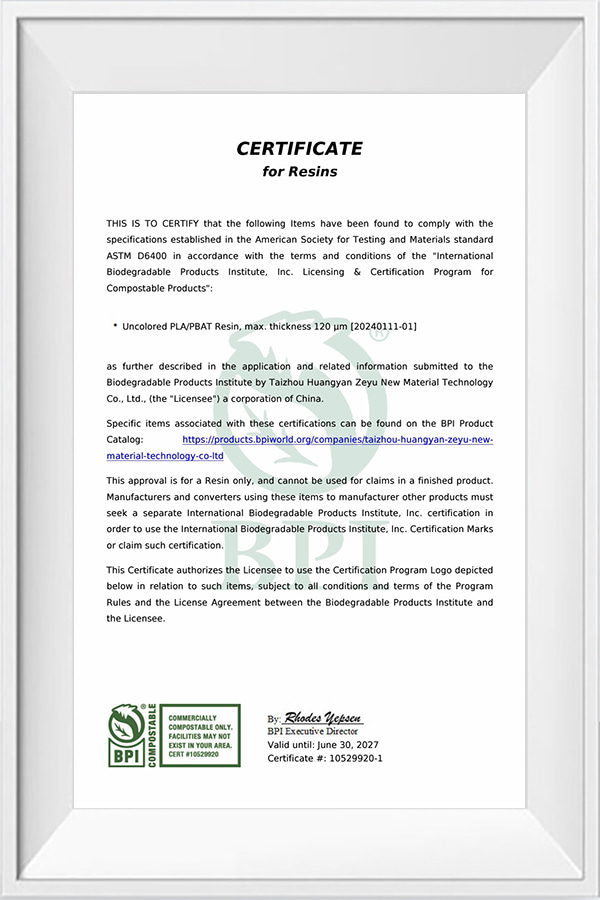

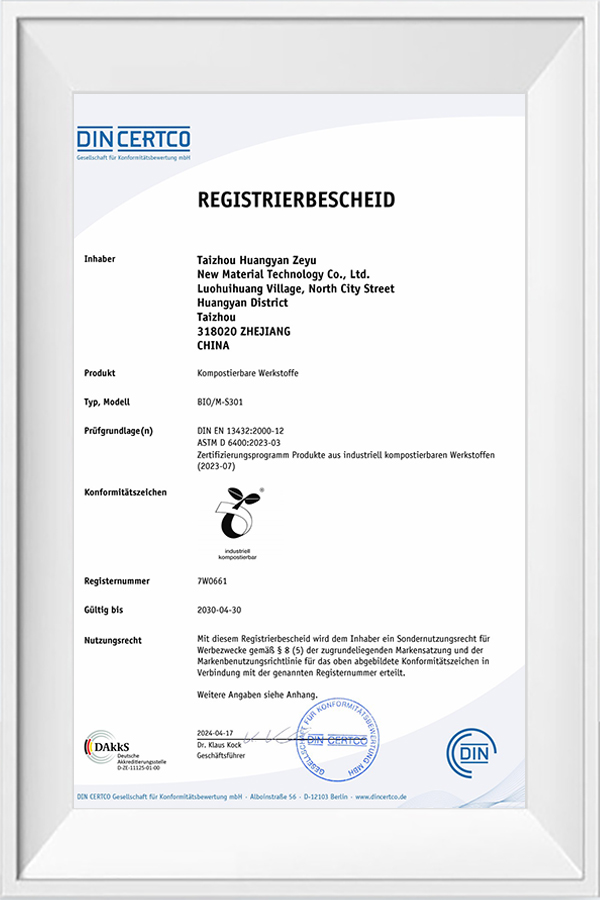

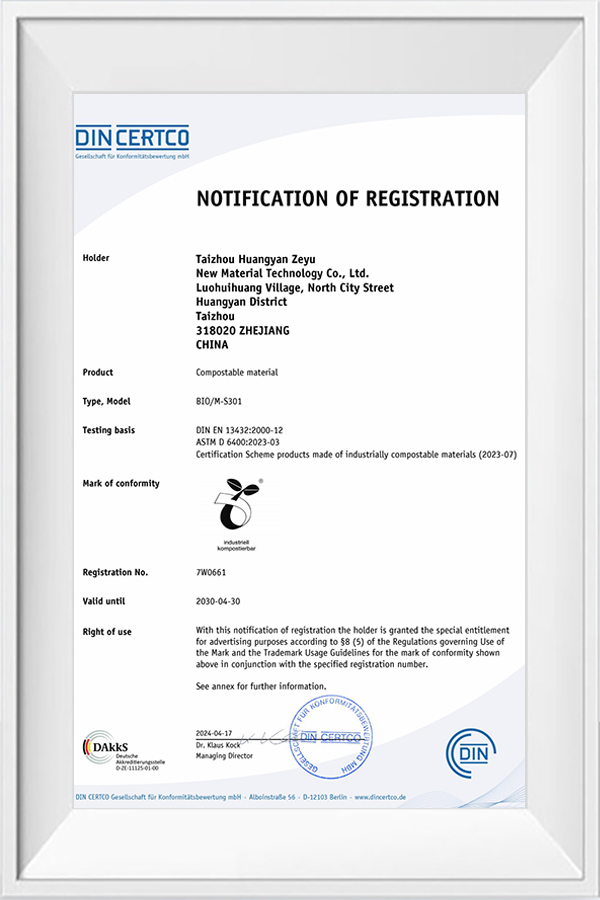

The core value of fully biodegradable straw materials lies in their excellent degradation performance. The material can be decomposed into water and carbon dioxide within 3 to 6 months through the action of microorganisms in the natural environment. It is non-toxic and harmless, does not produce residual microplastics, and significantly reduces soil and water pollution. This feature not only meets the national "dual carbon" strategy and the policy requirements of the "Plastic Restriction Order", but also conforms to the global environmental protection trend, and has natural adaptation advantages in markets such as the EU and North America. The material has been widely used to meet the environmental protection requirements of international standards such as EN 13432 and ASTM D6400, helping Chinese straw manufacturers to improve product added value and international competitiveness.

2. Equal emphasis on mechanical properties and user experience: adapt to high-frequency consumption scenarios

In order to ensure the durability and comfort of straws during daily drinking, the material has been scientifically formulated and modified, has good bending resistance and compression resistance, and is not easy to deform or break in hot and cold drink environments. Its physical properties are comparable to or even exceed those of ordinary plastic straws, truly realizing functional substitution. The material has a natural luster and a certain degree of transparency, a smooth taste and a soft texture, which can significantly improve the beverage consumption experience, especially suitable for mid-to-high-end beverage scenarios such as milk tea, coffee, and juice. In star restaurants, chain beverage stores, and takeaway platforms, it has become a key element to enhance the brand's environmental image and user satisfaction.

3. Strong processability: Adapt to the needs of industrial mass production

The material can be widely used in conventional process flows such as hot melt extrusion, injection molding, and hot pressing of existing straw equipment. It can be upgraded and replaced without changing equipment, which is conducive to the rapid transformation of production enterprises, reducing switching costs and improving production efficiency. This process compatibility makes it very suitable for large-scale and automated production modes, especially for responding to market demands for rapid delivery.

In the food packaging industry chain, the material can not only form an integrated green solution with environmentally friendly packaging products such as PLA cups and paper cups, but also be used as the basic material for customized straw production to meet personalized needs, such as colored straws, curved straws, packaged straws and other product forms, enhancing market diversity.

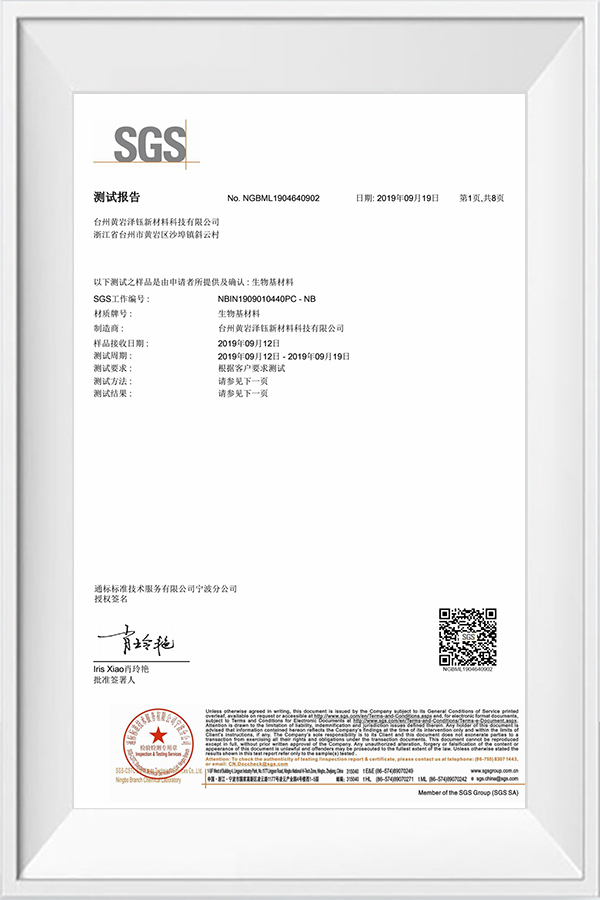

4. Safety and traceability: widely applicable to high-standard places of use

The fully biodegradable straw material is based on food-grade raw materials, which are clean and have clear sources. The product has passed domestic and foreign food contact safety certification to ensure safety in high-frequency drinking environments. When it is promoted and used in public places such as campuses, hospitals, government units, airports, and high-speed rail stations, it can not only effectively reduce disposable plastic waste, but also enhance the public's environmental awareness and help build a new social environment such as "plastic-free campus" and "green public service area".

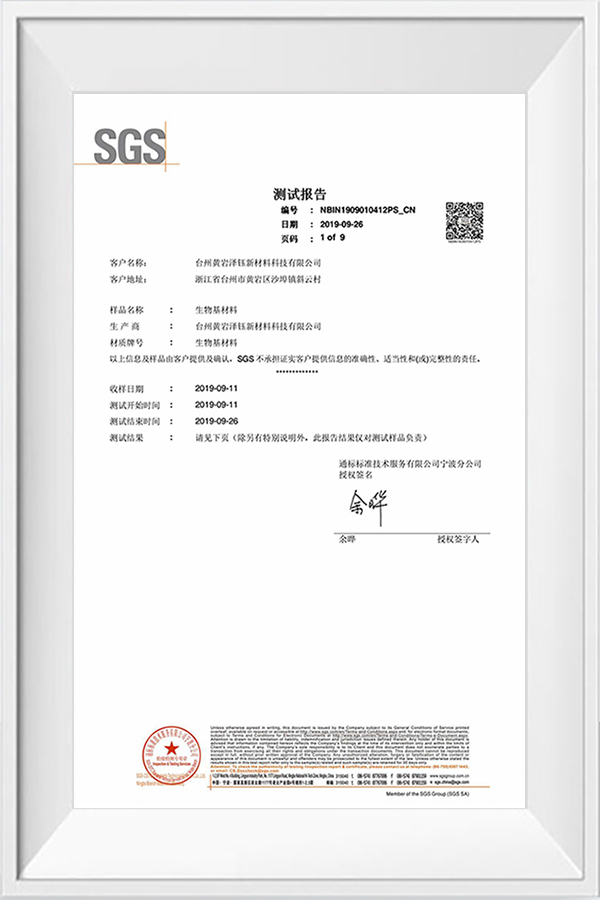

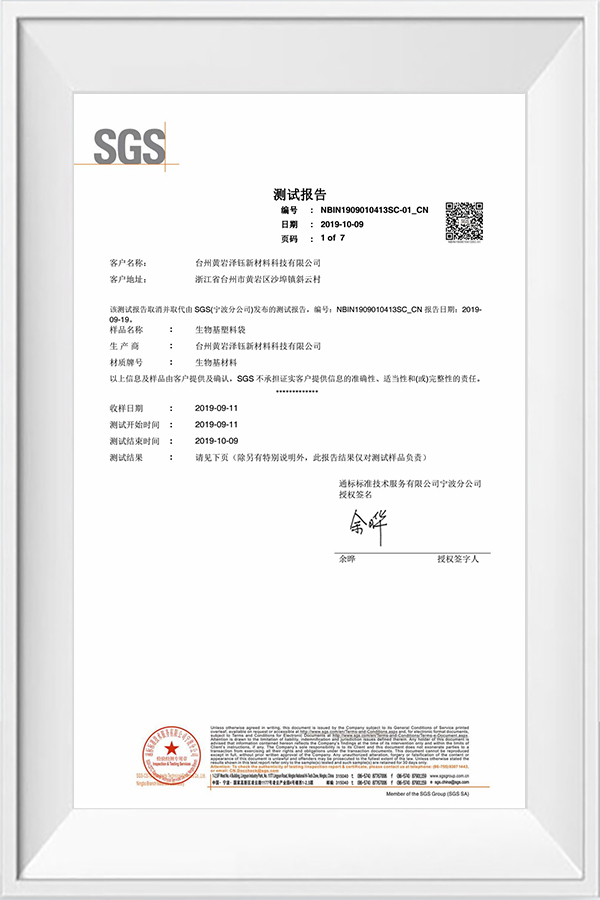

Enterprise advantages: Taizhou Huangyan Zeyu New Material Technology Co., Ltd.

As a high-tech enterprise focusing on the research and development and production of degradable new materials, Taizhou Huangyan Zeyu New Material Technology Co., Ltd. has always adhered to the development strategy of independent innovation and technology-driven. Focusing on core biodegradable materials such as PBAT and PLA, it has established a complete independent research and development system, and has achieved breakthroughs in many key technical fields, forming a differentiated advantage.

1. Own an independent R&D platform to promote continuous optimization and upgrading of materials

The company has established a research and development team composed of experts in multiple fields such as materials science, polymer engineering, and chemical processes. Relying on independent laboratories and pilot platforms, it continues to carry out systematic research on molecular structure regulation, blending modification, and performance enhancement of polyester-based biodegradable materials. In terms of the coordinated formula optimization of PBAT and PLA, the company has developed a number of special modification systems suitable for different processing scenarios. For example, for straw products, the company has launched compound materials with high thermal stability and good extrusion fluidity to ensure stable molding, smooth surface, and uniform tube wall during high-speed production.

2. Master the core formula system and form independent intellectual property results

After long-term accumulation and technological iteration, the company has successfully established a number of core material formulas with independent intellectual property rights, covering multiple product directions such as fully biodegradable films, injection molded products, and blow molded products. These formulas not only improve the flexibility, heat resistance, and film-forming properties of terminal products, but also solve the pain points of traditional PLA products such as high brittleness, narrow processing window, and easy deformation. Some key formulas have been granted national patents, and have shown good customer feedback and commercial conversion capabilities in market promotion, providing strong technical support for the company to continue to expand product application scenarios.

3. Integrate industry-university-research resources to build a technological innovation ecosystem

The company focuses on industry-university-research collaboration with universities and research institutes, and has carried out cooperative research with many well-known domestic universities in the fields of green degradable materials, bio-based polymerization technology, and material thermodynamic performance analysis. By sharing scientific research resources and platforms, the company continues to introduce advanced concepts and cutting-edge results to ensure that product development is always at the forefront of the industry.