What is PBST? What are its characteristics, performance and main application categories?

PBST is a fully biodegradable polyester material, which is an emerging environmentally friendly material in the polyester family. It is made by polycondensation of terephthalic acid and 1,4-butanediol. It has both the strength and thermal stability of polyester and good degradation ability. It is a more advanced type of material in the field of sustainable plastics.

The core characteristics of PBST are as follows:

Good thermal stability: PBST has a high melting point and excellent high-temperature performance. It still maintains mechanical stability in high-temperature processing or use scenarios, and is suitable for products that require heat resistance.

Strong UV and antioxidant ability: Compared with traditional degradable plastics such as PLA or PBS, PBST has stronger aging resistance in sunlight and air oxidation environments, and can adapt to more complex outdoor or long-term use conditions.

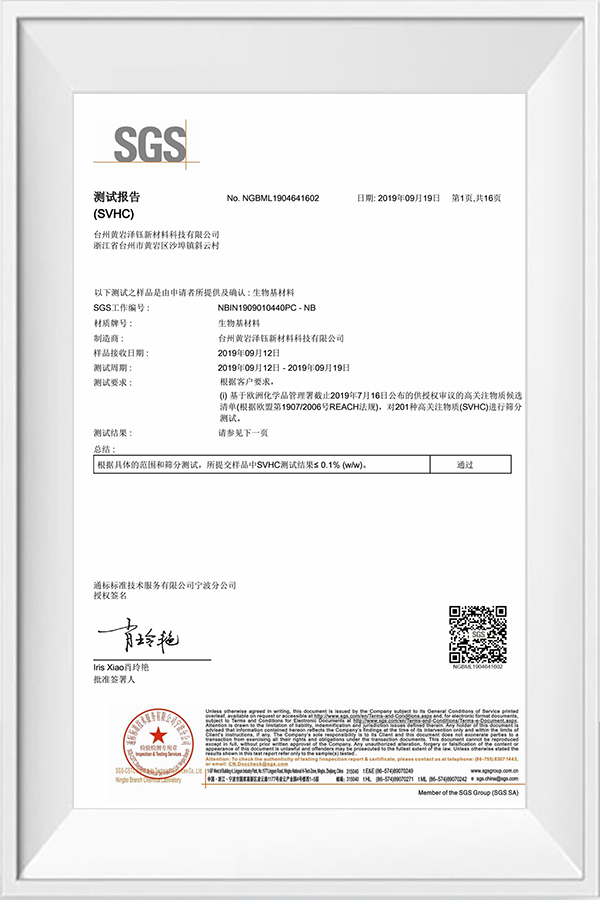

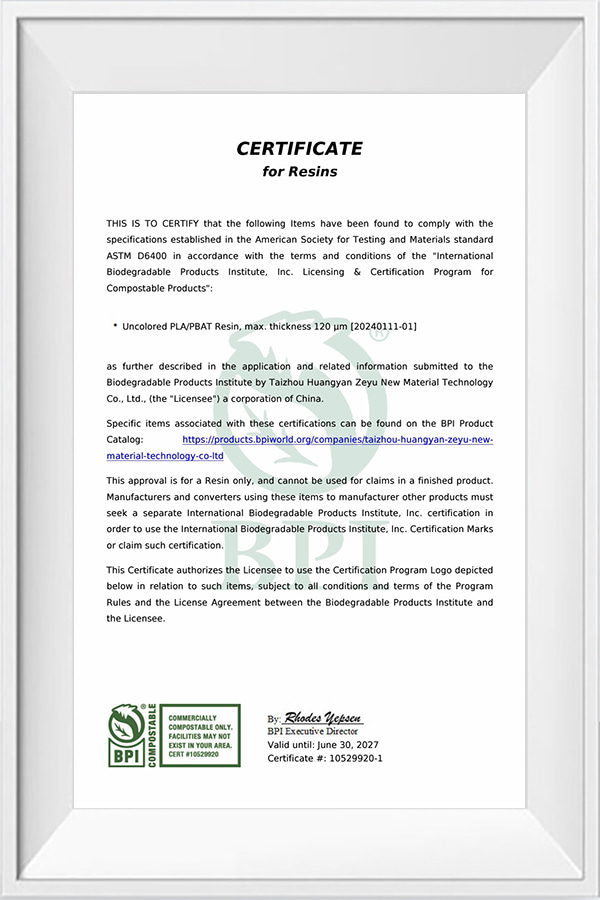

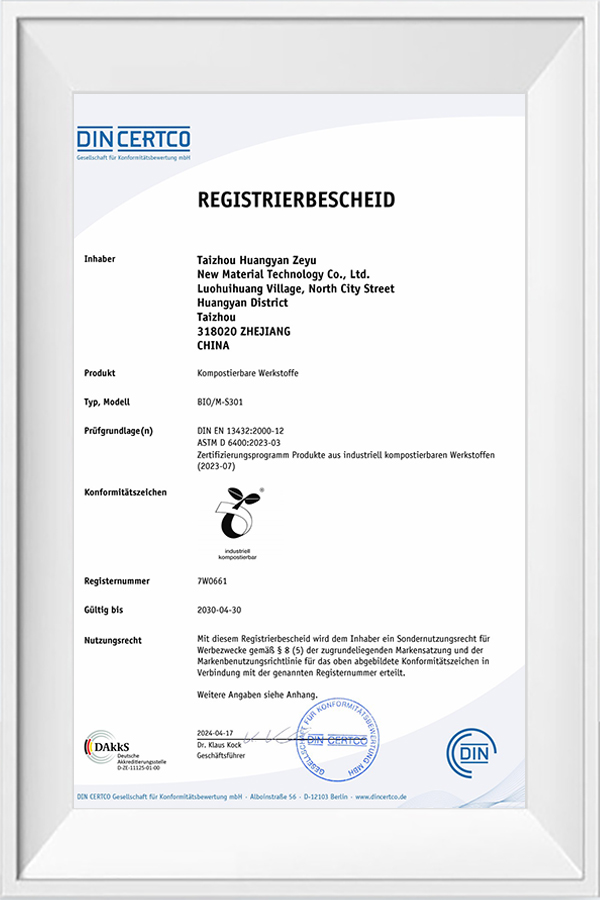

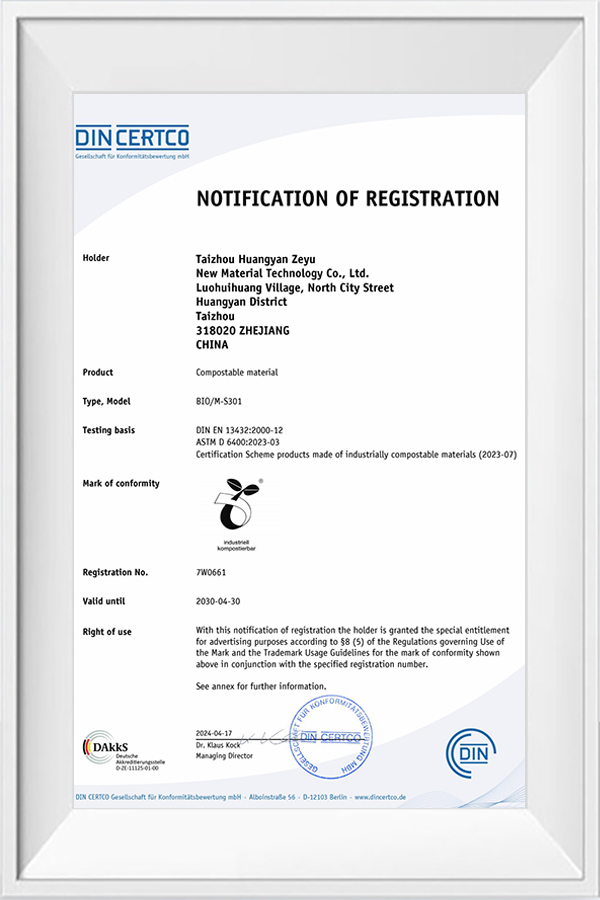

Fully biodegradable: In the natural environment, PBST can be effectively decomposed into carbon dioxide and water by microorganisms, without residual harmful microplastics, and meets the strict international standards for degradable plastics such as EN13432, ASTM D6400, etc.

Excellent mechanical properties: PBST has good tensile strength, toughness and flexibility. Its mechanical properties are comparable to those of some traditional engineering plastics and are suitable for fields with high requirements for strength and durability.

According to performance classification, PBST is particularly prominent in the following application scenarios:

High-performance packaging materials: such as cold chain transport packaging films, food trays, heat-sealed bags, etc. PBST's excellent heat sealing and low temperature resistance make it outstanding in the packaging field, and it is especially suitable for replacing PE/PET for degradable packaging solutions.

Textile and non-woven products: PBST fiber can be used in environmentally friendly textile fabrics, medical non-woven fabrics, wet wipes, sanitary napkins and other products. It has softness and hygroscopicity, and is safe to degrade.

Automotive interiors and industrial parts: In the automotive field, PBST can be used to replace some PVC or ABS materials for the manufacture of dashboards, interior parts, etc., meeting the simultaneous needs of green manufacturing and high performance.

Disposable consumer products: such as plastic bags, garbage bags, cling film, etc. PBST takes into account both service life and degradation ability, and is an ideal substitute for the "green transformation" of plastic products

Why does PBST stand out among environmentally friendly materials? What impact does it have on the ecology and the market?

Against the backdrop of increasing global plastic pollution and increasingly stringent environmental regulations, PBST has attracted much attention because it has successfully achieved the dual value of "strong performance" and "true environmental protection". It has great potential in the field of ecological protection and sustainable manufacturing, and is gradually becoming the representative of a new generation of green plastics.

From an environmental perspective:

Truly degradable: PBST will not remain in the environment for a long time like traditional plastics, and is also different from "photodegradable" or "oxidatively degradable" plastics. Its chemical structure can be enzymatically hydrolyzed into harmless small molecules by natural microorganisms, and it is completely degraded without secondary pollution.

Green life cycle: From raw material acquisition, production and processing to product use and recycling, PBST meets low-carbon emission and low-pollution standards throughout the process, which helps companies reduce their carbon footprint and improve ESG performance.

Low pressure to replace traditional plastics: PBST can be adapted to most existing plastic processing equipment (such as injection molding, film blowing, extrusion), and the threshold for alternative solutions is low, which is conducive to rapid promotion in the industry.

At the market level:

Global policy support for degradable plastics is increasing, including the EU plastic ban, China's "dual carbon" strategy, and the California Green Packaging Act in the United States, all of which include PBST in the list of materials to be encouraged and prioritized.

Consumers are more accepting of green products, especially in the fields of food packaging, daily plastics, and maternal and child products. Environmentally friendly, safe, and non-toxic materials have become important labels for product upgrades.

Compared with other degradable materials (such as PLA), PBST has higher heat resistance and weather resistance, so it remains stable under more complex working conditions, broadening its application boundaries.

How does Taizhou Huangyan Zeyu New Material Technology Co., Ltd. promote the industrialization and green application of PBST?

As a leading domestic manufacturer of bio-based degradable materials, Taizhou Huangyan Zeyu New Material Technology Co., Ltd. is deeply involved in the field of environmentally friendly materials and is committed to promoting green upgrades in the plastics industry through technological innovation and ecological responsibility. The company plays a dual role as a bridge and engine in the research and development, production, and market expansion of PBST and related bio-based plastics.

Zeyu New Materials has always adhered to the development concept of "green raw materials, green manufacturing, and green life". The plastic bags and cling film products it produces are all made of fully degradable and renewable materials such as PBST, with the following core advantages:

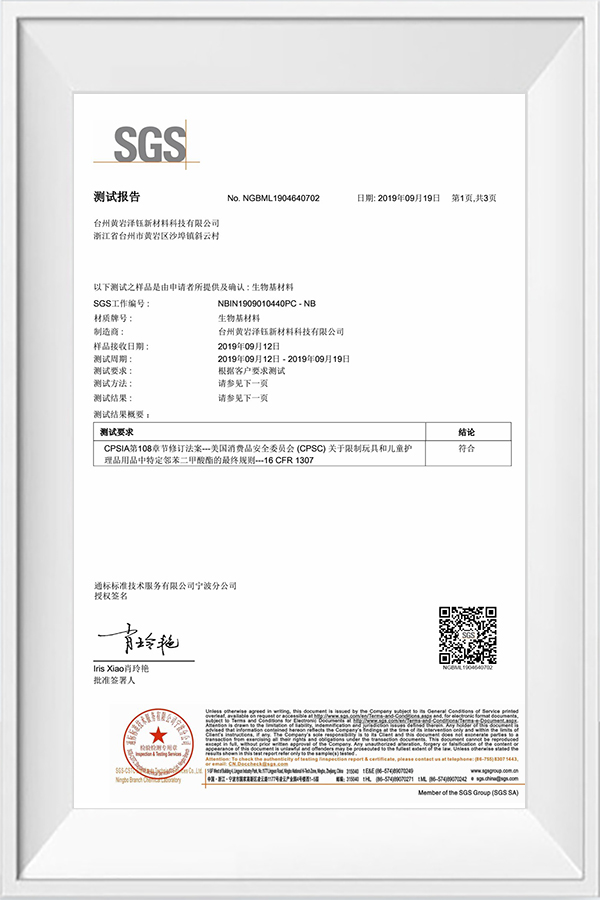

Completely degradable and in line with global environmental standards: The PBST raw materials and products produced by the company can pass international certifications such as EN13432 and ASTM D6400, adapt to global green regulations, and help customers expand international markets.

Full life cycle environmental protection design: Zeyu products are in line with environmental protection concepts from the source of raw materials, production control to use and degradation. The whole process not only reduces the consumption of petrochemical resources, but also avoids the environmental embarrassment of "nowhere to deal with after use".

High-performance plastic bag and packaging film solutions: The bioplastic bags, garbage bags, express bags and cling films developed by Zeyu based on PBST have good flexibility, heat sealing and low temperature resistance, and are widely used in supermarkets, takeout, retail, e-commerce logistics and other fields.

Help corporate customers achieve ESG goals: Zeyu is not only a material supplier, but also a partner in green transformation, helping companies provide integrated solution support in green procurement and environmentally friendly packaging upgrades.