What is PHA? What are its sources and core advantages?

PHA is a type of fully bio-based, fully biodegradable polymer material synthesized by microorganisms through fermentation of renewable carbon sources (such as vegetable oils, starch, sugars, agricultural waste, etc.). As a representative of the next generation of environmentally friendly materials, PHA has mechanical properties comparable to traditional plastics, and can be completely degraded into water, carbon dioxide and biomass in the natural environment, without forming "white pollution" or "microplastic residues". Its green, safe and sustainable nature is attracting great attention from environmental protection organizations and manufacturers around the world.

The core features of PHA include:

Complete biodegradability: PHA can be degraded in a variety of natural environments such as soil, seawater, fresh water, and compost, usually within a few weeks to months. The final product is non-toxic and harmless, and is one of the few marine degradable materials.

Good biocompatibility and non-toxicity: PHA can be accepted by human tissues without worrying about toxic side effects. It has been widely used in high-end medical scenarios such as medical sutures and drug sustained-release systems.

Adjustable mechanical properties: Different types of PHAs have diversity in rigidity, flexibility, and toughness, which facilitates material modification and performance optimization according to different uses.

Environmentally friendly, green manufacturing: Raw materials come from nature and can be obtained through renewable resources such as sugars and vegetable oils. The production process has low carbon emissions and low energy consumption, and the carbon footprint of the life cycle is far better than petrochemical plastics.

Combination of materials science and biomanufacturing

PHA is the product of the cross-integration of microorganisms and materials science. Currently, a variety of engineered strains (such as Escherichia coli, Pseudomonas, etc.) can efficiently synthesize PHA. In addition, the rapid development of synthetic biology, enzyme engineering and fermentation control technology makes the production of PHA more feasible and commercially potential.

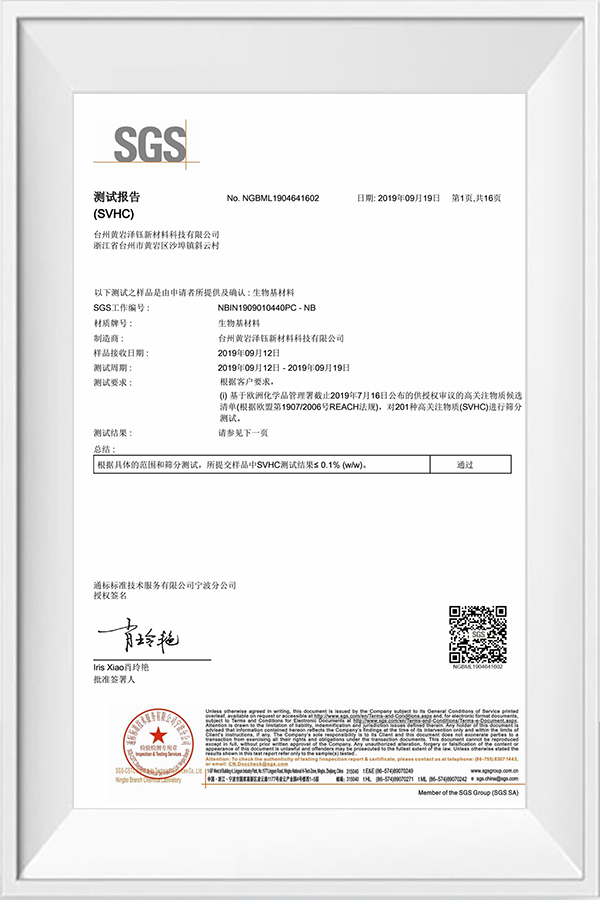

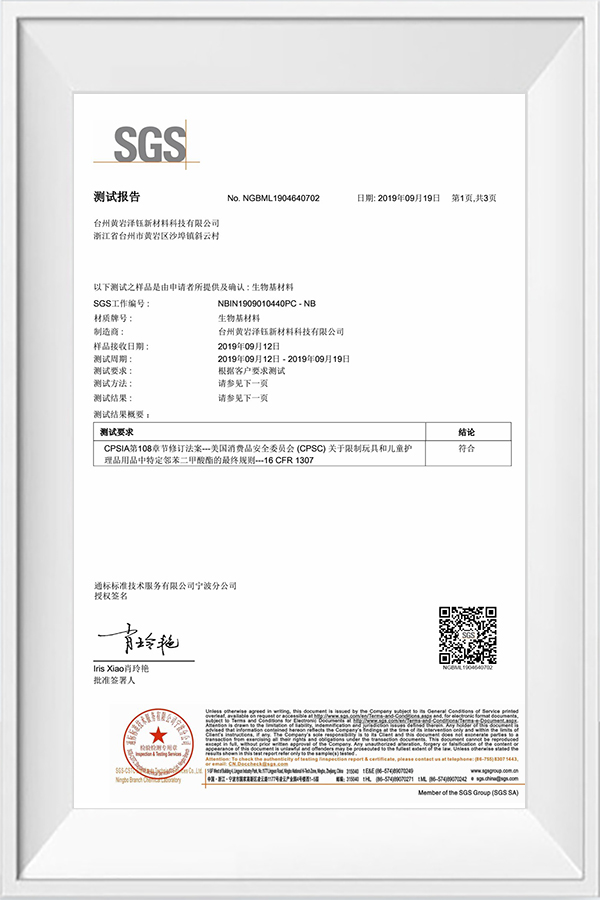

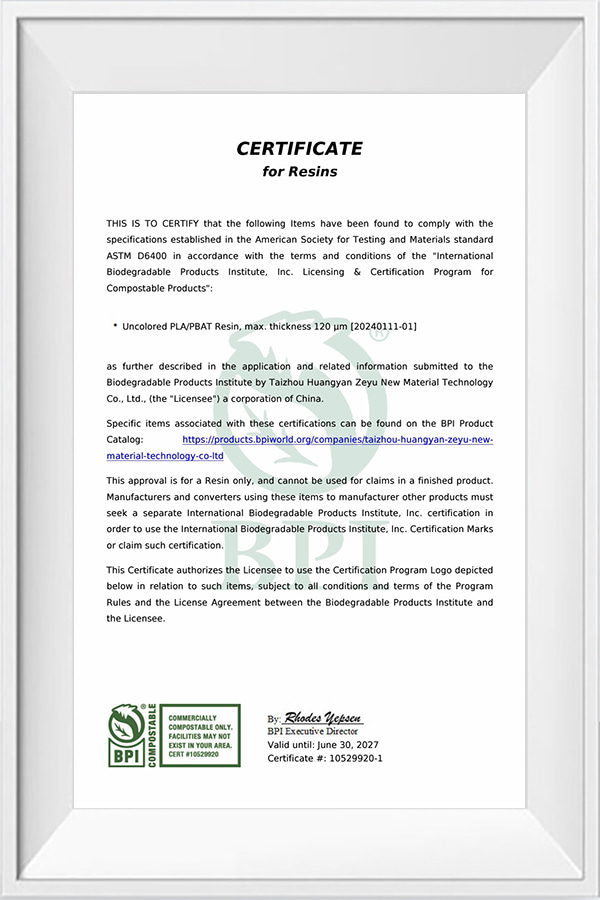

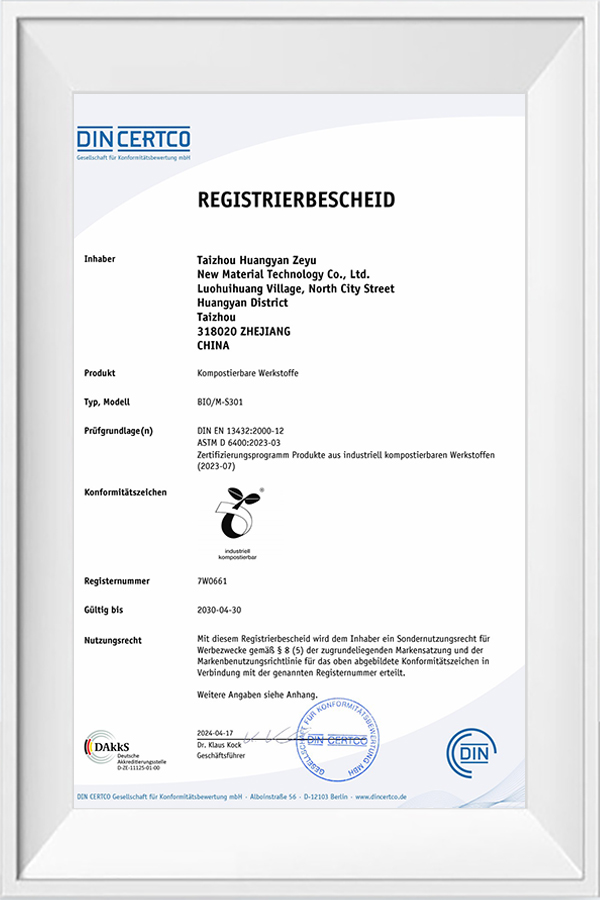

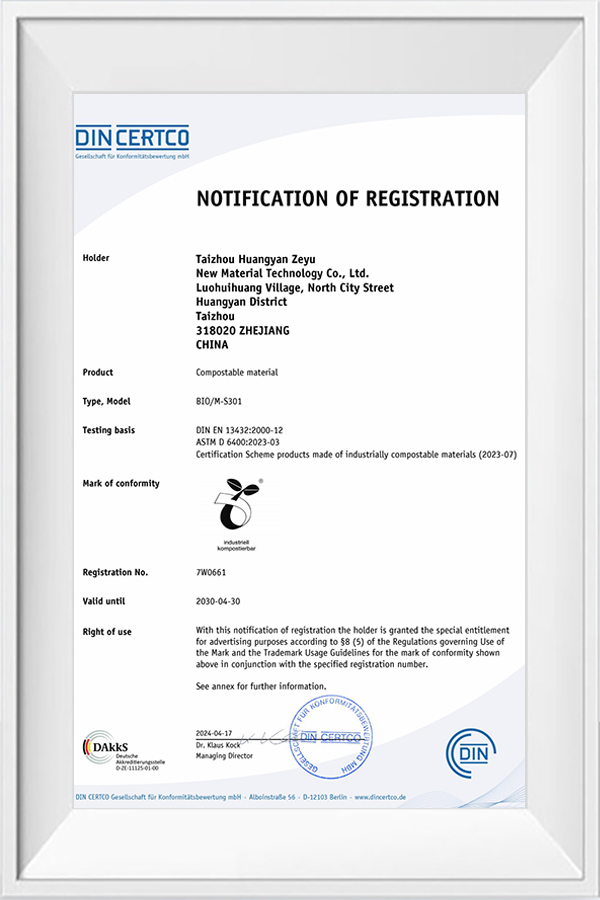

Taizhou Huangyan Zeyu New Material Technology Co., Ltd. relies on its strong professional R&D team and the "integration of industry, academia and research" with domestic top scientific research institutions (such as the Institute of Physical Chemistry of the Chinese Academy of Sciences, Ningbo Institute of Materials, and Beijing Technology and Business University) to continuously promote scientific research breakthroughs and industrial implementation of PHA materials. It has realized the engineering application of multiple PHA grade materials and provided global users with green, safe and degradable new material solutions.

In what fields is PHA mainly used? What are its advantages compared with traditional materials or other degradable materials?

Due to its unique structure, green source and degradable properties, PHA performs well in many key application fields and is an ideal material choice for achieving "plastic replacement" and "environmental friendliness". The following are typical application classifications of PHA and their corresponding advantages:

1. Medical field

PHA has good biocompatibility and absorbability, and is suitable for: absorbable surgical sutures; tissue engineering scaffolds; sustained-release drug carriers (microspheres, nanoparticles); medical dressings, bone nails, etc.

Compared with PLA or other synthetic polymers, PHA degrades more thoroughly in the body, has no inflammatory response, and is friendly to metabolic byproducts. It is one of the few bioabsorbable medical polymer materials certified by the FDA.

2. Packaging and disposables

PHA is suitable for: take-out boxes, beverage cup lids; food packaging films; express bags, shopping bags; cold chain transportation packaging.

Due to its excellent mechanical properties and environmental degradation, PHA can be degraded under natural conditions without the need for special industrial composting conditions. It is more environmentally friendly than materials such as PLA and PBAT, and is especially suitable for use in marine sensitive areas and areas with high environmental protection supervision.

3. Agricultural applications

Degradable mulch, seedling tray; pesticide slow-release coating; biological fertilizer carrier.

Agricultural mulch traditionally uses PE materials, which easily causes soil residual film pollution. After use, PHA mulch can be degraded into biomass and carbon dioxide in cultivated land without manual recycling, which is an important boost to the development of green agriculture.

4. Environmental protection and degradable alternatives

Tableware (knife, fork and spoon); straws; disposable medical waste products (such as gloves and bedpans).

Because PHA has the characteristics of non-toxicity and complete degradation, it is suitable for "discarded after use" scenarios, reducing the volume of plastic waste and reducing interference with the natural ecology.

What is the development trend of the PHA industry? How can companies seize new opportunities in green materials?

In recent years, as the world's awareness of the "plastic pollution" crisis deepens, policies, technological breakthroughs and consumer concepts of various countries are pushing PHA into a stage of rapid growth. As an emerging green material, PHA has shown significant development potential and market prospects.

Industry trends and prospects:

1. Policy guidance continues to strengthen

2. Technology gradually matures and costs continue to optimize

3. Multiple industries enter the market, competition and collaboration coexist

For professional material companies like Taizhou Huangyan Zeyu New Material Technology Co., Ltd., start to grasp the PHA trend from the following aspects:

1. Relying on scientific research advantages to promote innovation: Give full play to the company's strong research and development team composed of professors and doctors, continue to promote the performance modification and cost control of PHA materials, explore the blending system with PLA and PBAT, and improve process adaptability.

2. Strengthen the integration mechanism of industry, academia and research: maintain cutting-edge research sharing with institutions such as the Chinese Academy of Sciences and Ningbo Institute of Materials, and quickly transform laboratory results into commercializable PHA products and processing solutions to seize the initiative.

3. Expand industry implementation scenarios: Develop customized PHA material grades for application scenarios such as medical devices, packaging materials, agricultural films, and mulch films to meet the differentiated needs of different industries and increase market penetration.

4. Build international brand influence: With the help of global green policies and environmental protection trends, create the brand image of "PHA ecological solutions", participate in international standard setting and industry exhibitions, and win customer trust and market voice.